In this article, you will learn all the important aspects of heat pump maintenance to ensure optimum performance.

With simple checks, you can increase the efficiency of your heat pumps and reduce your operating costs in the long term.

Download the free checklist and get a detailed step-by-step maintenance guide to identify potential problems and ensure long-term efficiency.

Why should you have your heat pump serviced regularly?

Compared to conventional heating systems such as gas or oil heating, heat pumps are low-maintenance.

The reason for this is that they work without burning fossil fuels and are made from durable components.

Specialists from the field of facilities management advise regular inspections despite the low maintenance requirements, as these intervals can save up to a quarter of the electricity consumption.

In addition, regular servicing and minor maintenance work significantly extends the service life of the system and its components. This reduces maintenance costs and downtime risks, resulting in optimized asset asset management.

As part of predictive maintenance in facility management, it makes sense to check heat pumps at fixed intervals. This ensures that the system always runs efficiently and trouble-free.

In addition, scheduled maintenance avoids longer interruptions to operation and ensures comfort and safety for the building’s users.

Good to know:

Heat pumps break down briefly during maintenance, so it is advisable to carry this out in summer when heating is not required.

Is heat pump maintenance mandatory?

The Federal Office of Economics and Export Control (BAFA) prescribes regular maintenance for heat pumps that have been subsidized through its funding programs. The heat pump is tested one year after installation.

Whether mandatory or not, those who have their heat pumps checked regularly benefit in several ways: many heat pump manufacturers offer extended warranties if appropriate maintenance contracts are concluded or regular maintenance is carried out during the first few years of operation.

According to EU Regulation 517/2014 systems with certain refrigerants must be checked regularly for leaks. This applies to heat pumps, air conditioning and refrigeration systems that use fluorinated greenhouse gases in a defined minimum quantity of 5 tons of CO2 equivalent.

System operators must ensure that these leak tests are carried out at the prescribed intervals. The date of the next inspection is then based on the date of the last inspection.

Important:

In building management, every system deserves special attention. No matter whether it is the maintenance of smoke detectors, fire protection systems or ventilation systems – it is important to familiarize yourself with all legal obligations and to draw up a specific maintenance plan for each system.

The operator is obliged to regularly inspect and maintain his systems in order to fulfill his operator responsibility to fulfill his operator responsibility.

- With these maintenance plan templates increase effectiveness.

- Fire protection documentation: Managing and organizing for a safe fire safety strategy.

How often does a heat pump need to be serviced?

There are no legally prescribed maintenance intervals for privately used heat pumps, but an annual inspection of the systems is recommended. The exact period between inspections depends on characteristics such as the design and pump technology used.

Heat pump types at a glance

- Air-to-water heat pump (air heat pump): The thermal energy is extracted from the ambient air and fed into the heating circuit.

- Brine water heat pump (geothermal heat pump): Extracts heat directly from the ground. For this purpose, either several 100-meter-deep geothermal probes or a shallow collector are used to tap the heat stored in the ground.

- Water-to-water heat pump (groundwater heat pumps): uses the groundwater a few meters below the earth’s surface as a heat source. The groundwater heat is extracted from a well or collector to a maximum depth of 20 meters and fed into the heating circuit.

What maintenance is required for a heat pump?

The exact steps for maintaining a heat pump depend on the type of heat pump.

As a rule, the specialist always checks the hydraulic and electrical connections and joints as well as the refrigeration circuit for leaks.

In addition, the specialist company always carries out an inspection of the connected hot water and heating system with pumps, filters, etc.

Depending on the heat pump model and manufacturer, further maintenance work may be required.

Maintenance of air-to-water heat pumps

With the air heat pump, it is particularly important that the air intake and outlet openings are checked and cleaned if necessary. In addition, the specialist checks the condensate tray and the drains where the humidity is drained off.

The maintenance technician must ensure that there are no blockages or impurities. If necessary – usually every three years – the air heat exchanger is professionally cleaned.

Maintenance of geothermal heat pump

If you have a brine-to-water heat pump, the specialist will check whether the frost protection is sufficient during regular maintenance.

Its maintenance protocol includes checking the chemical composition of the brine, checking for leaks and measuring the pressure. The brine is refilled as required and leaks are repaired. The heat circuit filter is also cleaned.

Maintenance of groundwater heat pump

In the case of a water-to-water heat pump, the company regularly checks the wells and pumps. The components checked include valves and filters.

The visual inspection of the well ensures that deposited water impurities do not lead to wear and thus impair the performance of the heat pump.

The following table provides an overview of the various system requirements:

| Type of heat pump | Maintenance tasks |

|---|---|

| All | Leak test |

| Check all | Check components for signs of wear |

| All | Checking the system pressure and system temperature |

| Air-water heat pump | Inspection (and cleaning if necessary) of the supply and exhaust air ducts for indoor systems |

| Air-water heat pump | Checking the condensate drain |

| Brine water heat pump | Checking (and topping up if necessary) the brine to ensure frost protection |

| Brine water heat pump | Checking (and cleaning if necessary) the filters |

| Brine water heat pump | Pressure measurement to discuss possible leaks |

| Geothermal heat pump | Checking the brine pipes for condensate |

| Water Water heat pump | Visual inspection of the well system |

| Water Water heat pump | Inspection of filters, valves and pumps |

Heat pump maintenance: What you can do yourself and when a specialist is required

To get the most out of your heat pump, it is advisable to have maintenance carried out by a professional specialist company.

However, you can also help to extend the functionality of your system yourself.

Here is an example of how you can carry out maintenance on a heat pump yourself:

We have put together tasks for maintaining your heat pumps that you can do yourself. The checklist can also serve as proof of implementation.

Heat pump parts in need of maintenance and typical defects

If you operate a heat pump, you should pay particular attention to the compressor and pumps: They are susceptible to wear and tear and breakdowns.

The compressor generates mechanical friction and runs under high pressure and temperature fluctuations. Insufficient lubrication can lead to permanent damage. The same applies to the circulation pumps, which draw in the heating water and are also subject to wear.

Other critical components are valves and fans. Valves control the coolant flow and must be checked for leaks. Fan motors are unprotected against the effects of weather and dust and their bearings can become defective.

Use of digital solutions for optimal organization and documentation of heat pump maintenance

Follow these three simple steps to optimize your heat pump maintenance:

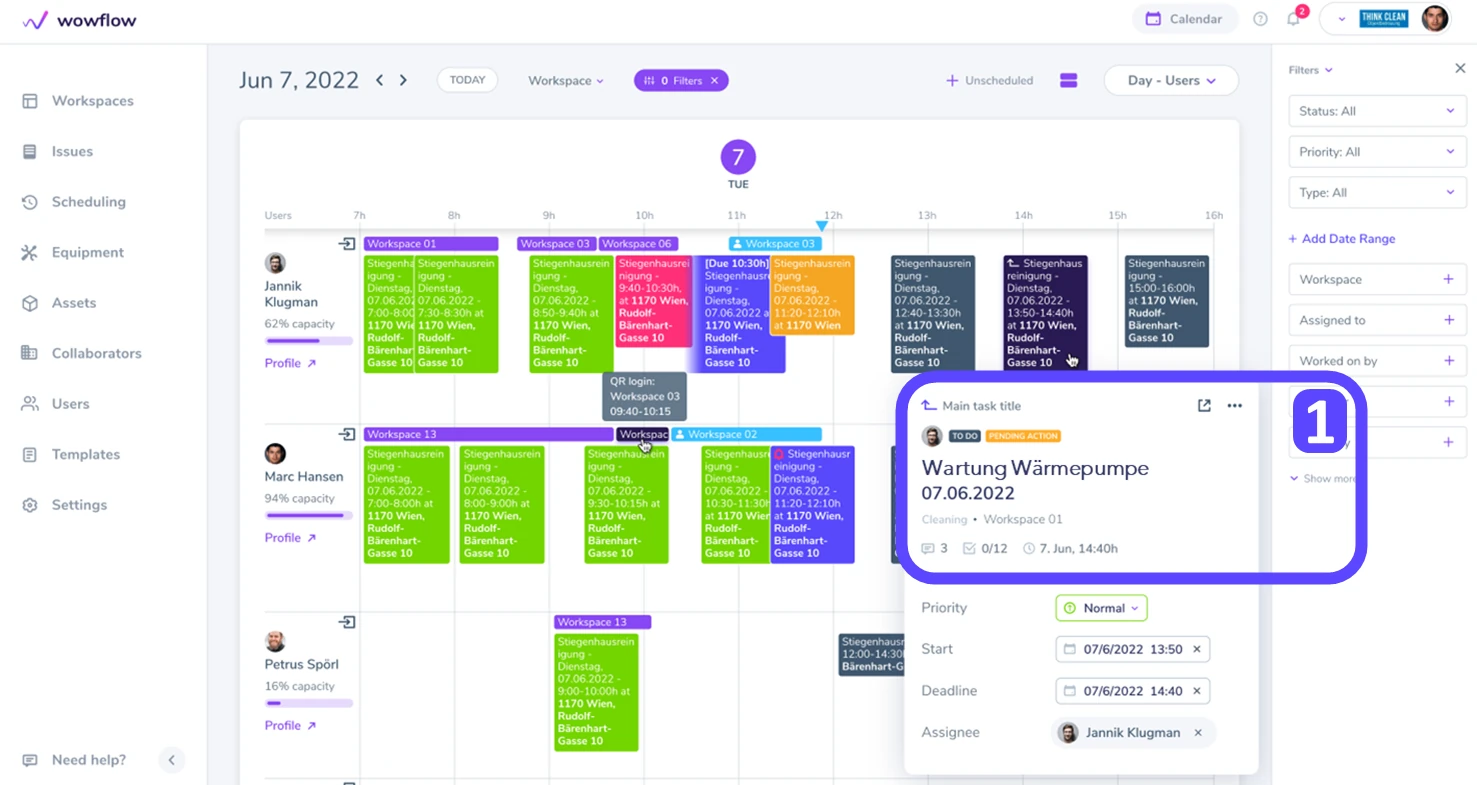

1. Plan recurring maintenance appointments in the app with the practical calendar view

With Wowflow’s practical calendar view, you’ll never miss a maintenance appointment.

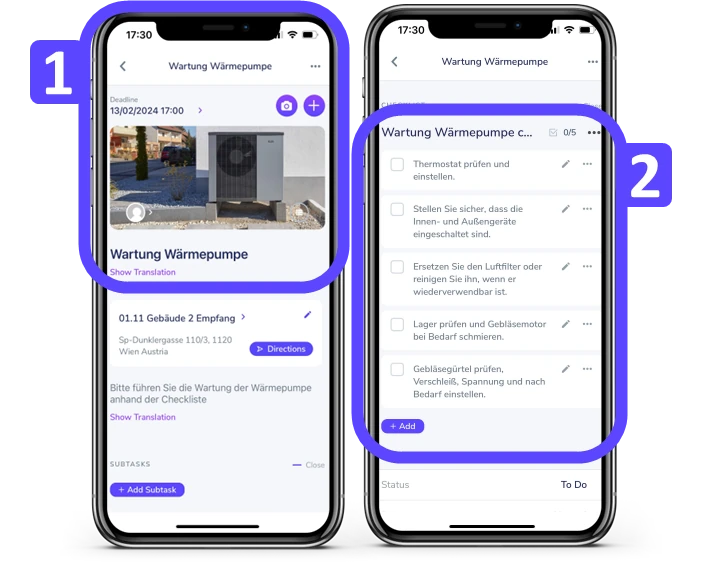

2. Carry out maintenance on the heat pump

Your maintenance team has access to all relevant information via the mobile app and uses the checklist to carry out the maintenance task. Additional images and comments are added automatically.

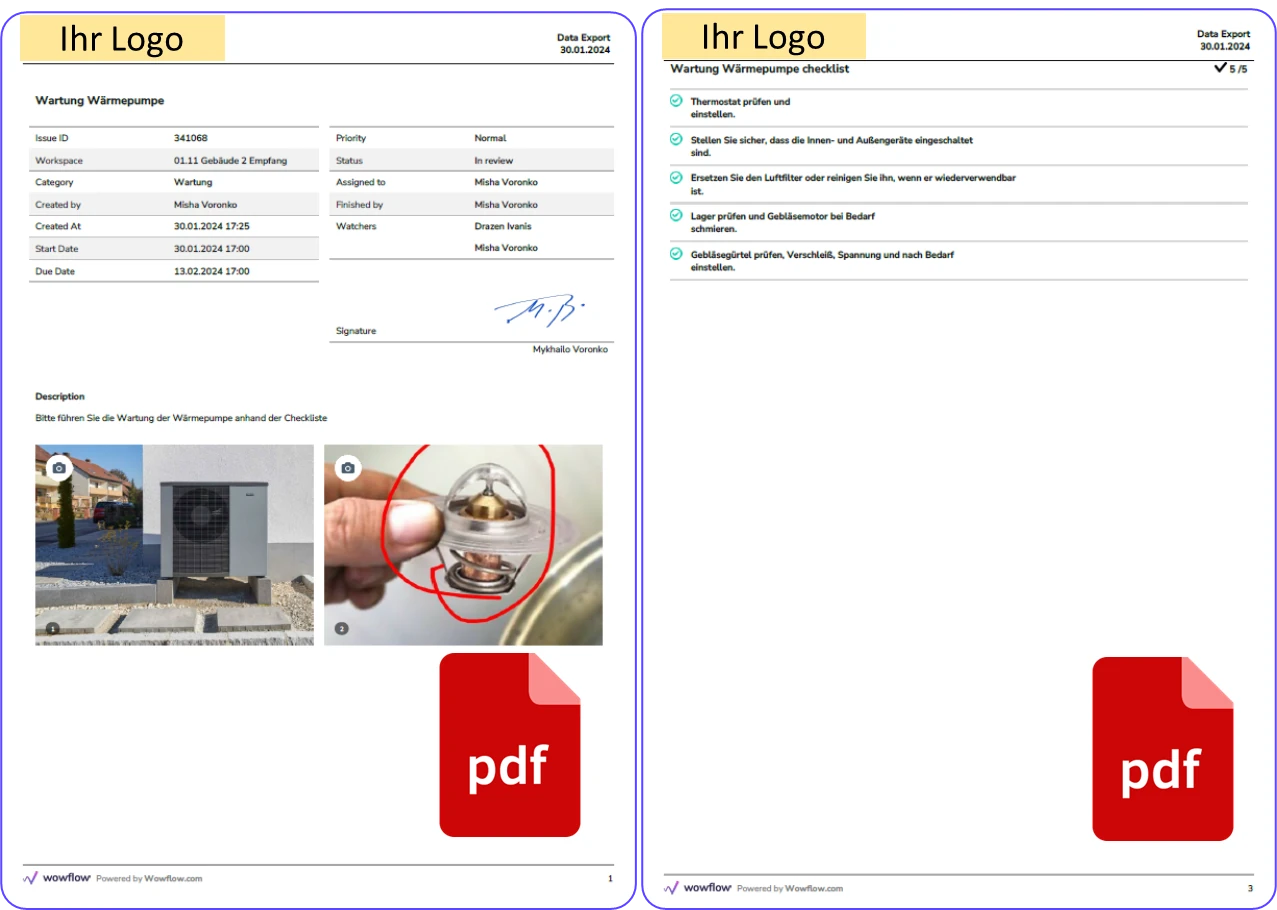

3. Create automated maintenance reports in PDF format:

- Once the maintenance work has been completed, you can generate professional PDF reports with just one click.

- Do you need a signed confirmation as official proof? Fast and legally compliant with the PDF signature.

- Save your reports in Wowflow with advanced filter options or simply export the data to your ERP/CAFM-tool.

Keep an eye on your maintenance processes with Wowflow.

Conclusion

Regular maintenance of heat pumps is crucial to ensure optimum performance and longevity. Potential problems can be identified at an early stage by checking important components.

This helps to avoid expensive repairs and breakdowns. The use of a special maintenance checklist can help to systematically work through all relevant steps.

Simplify your maintenance processes with Wowflow. Download the app to organize your maintenance tasks and easily upload checklists. Optimize the performance of your heat pump and avoid expensive breakdowns.

Frequently asked questions

What is the service life of a heat pump?

The average service life of heat pumps is usually around 15 to 20 years. With particularly good maintenance, however, it can also be operated for more than 30 years.

Heat pump maintenance costs: How much does the annual maintenance of a heat pump cost?

The average cost of maintaining a heat pump is around €150. These costs do not cover the installation or replacement of any spare parts that may be required.

It is important to note that, depending on the type of heat pump, maintenance work involves different levels of effort, which can lead to additional costs. However, annual maintenance, including travel, should not cost more than €300.

What consequences can neglected maintenance have?

Neglecting maintenance can have various negative consequences for the heat pump. On the one hand, the performance of the system is reduced because soiling or damage to components is not noticed and rectified. Power consumption can also increase due to power losses.

In addition, the risk of major failures or even damage, for example to the motor or control unit, increases. If defects occur, they can often only be rectified by costly repairs.

Regular maintenance, on the other hand, ensures the reliability, efficiency and service life of the heat pump system.