Would you like to create and use a test report? You may be wondering what an audit trail actually is and how it can help your company. Legally compliant documentation of audits in the facility management industry is essential, but there is often uncertainty as to the best way to carry them out.

In this article you will find all the information you need. Learn how to create, correctly use and document test reports. Use our practical test report templates, which can serve as a useful guide.

The correct implementation of test protocols can be a challenge. We will therefore also show you how you can successfully manage this task with the help of software.

Request

What is an inspection report?

An inspection report is an important document that contains the detailed execution and results of a technical and often electrical inspection. The protocol describes who exactly checked which aspects, how and when the audit was completed, what results were achieved and what measures were subsequently taken.

Test protocol: Purpose

The purpose of the test report is to enable legally compliant verification and documentation of tests on technical systems and devices. It offers future inspectors the opportunity to gain a comprehensive insight into the condition of the operating equipment in order to improve asset management to ensure better asset management.

In addition, according to §14 of the German Ordinance on Industrial Safety and Health (BetrSichV), the employer must ensure that the results of all tests are properly documented. The test report helps the operator to fulfill these legal obligations by documenting the condition of the equipment, any defects and any maintenance precisely.

In the event of damage, the employer can use an inspection report to prove that the devices, systems or machines have been properly inspected. A legally compliant test report is considered proof in court that the operator has fulfilled their duty of care when inspecting electrical systems.

Proper documentation can even protect you from considerable costs in the millions in the event of accidents or fires.

Overall, the test report is therefore an indispensable tool for ensuring the safety and efficiency of operating equipment.

An inspection report is a document that contains detailed records of the results and findings of an inspection or test.

A test report fulfills various purposes:

- Information: The test report provides the specialist personnel with detailed information on the condition of the operating equipment.

- Safety: The test log is used to check and document technical systems and devices in order to identify and minimize potential safety risks.

- Compliance: The audit trail enables compliance with legal requirements by ensuring proper documentation of audits in accordance with applicable regulations.

- Duty of care: The test report serves as proof that the operator has fulfilled his duty of care in order to avert possible liability claims.

The test protocol plays an important role in fulfilling the operator responsibility.

Test protocols in practice: responsibility and obligations for companies

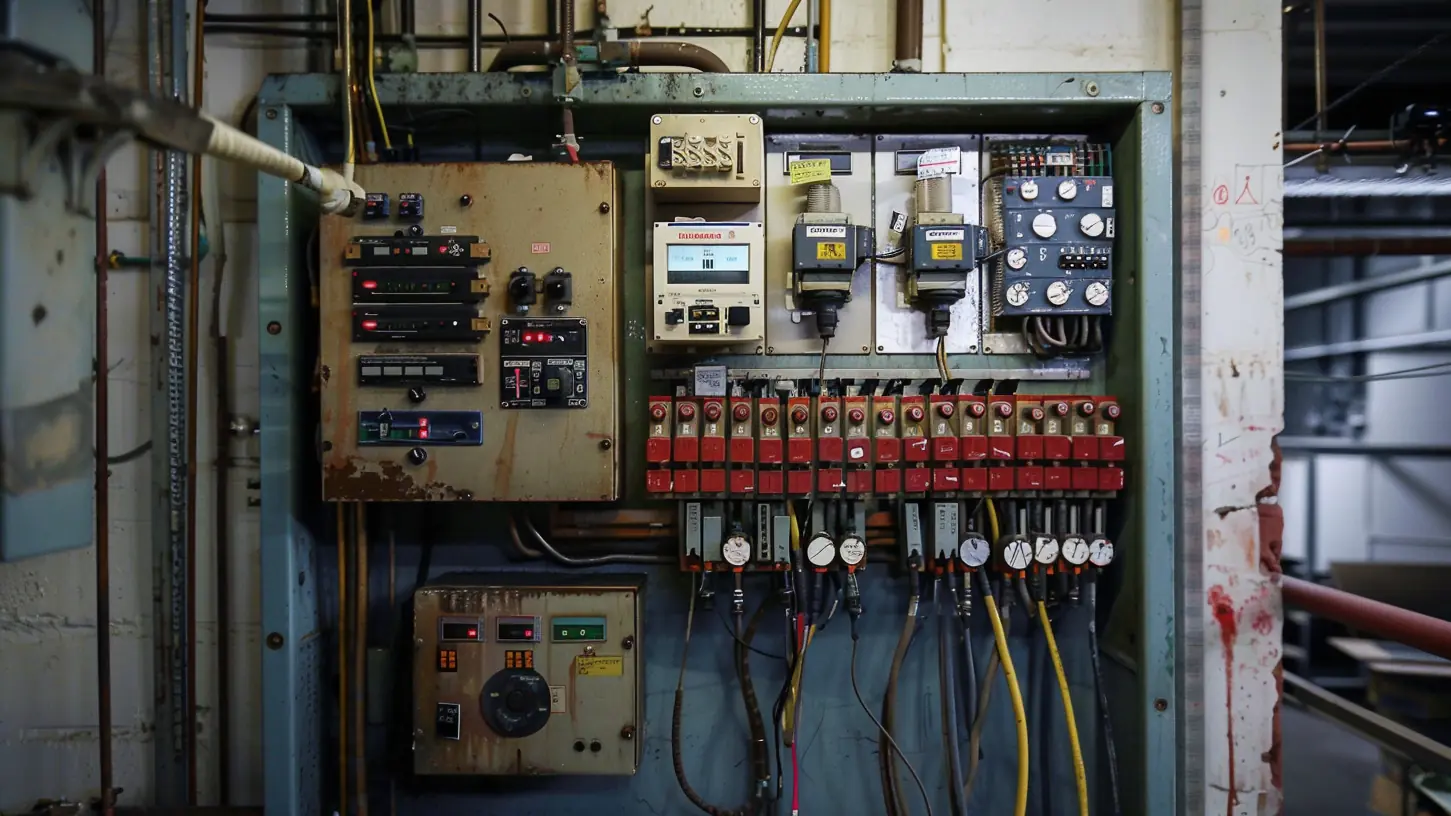

Companies are responsible for the safety of electrical systems and devices. In this section, we will go into detail about the specific obligations that companies have in relation to audit trails. Find out what specific responsibilities and tasks you have as an entrepreneur.

Which companies have to create test protocols?

Every company that works with electrical systems and devices must carry out this documentation. This applies to various businesses such as industrial plants, office buildings and other facilities where security plays an important role in facility management.

School buildings, production facilities or hotels: everyone must ensure that all devices and systems not only work, but also comply with the applicable safety standards.

Good to know

In facilities management, inspection logs ensure complete system documentation.

The test logs form an indispensable part of the documentation for fulfilling operator responsibility. Together with the as-built documentation, inspection logs form the solution for fulfilling operator responsibility.

Why is it necessary to create a test report?

An electrical accident at work often has life-threatening consequences. For this reason, legislators and accident insurance institutions have introduced stricter safety standards for electrical systems and equipment.

In contrast to other tests such as the ÖNORM B1300 where application is voluntary, the Industrial Safety Regulation and the accident prevention regulation DGUV Regulation 3 ‘Electrical installations and equipment’ stipulate that tests must be carried out regularly.

In addition, testing obligations are contained in a large number of other regulations, such as the Product Safety Act, the Energy Industry Act, and the state building regulations.

This means that companies in different industries are responsible for creating test protocols to ensure the safety of their electrical systems and devices.

Request

What exactly does DGUV3 say?

DGUV Regulation 3 requires every company that uses electrical equipment to comply with certain principles in accordance with Section 3.

In accordance with Section 5 of DGUV Regulation 3, the employer is responsible for the proper testing of electrical systems and equipment. The tests must be carried out in the following cases:

- Before the systems and equipment are commissioned for the first time,

- After a modification or servicing before recommissioning,

- At regular intervals to maintain the proper condition

- By a qualified electrician or under their direction and supervision.

Section 5 of DGUV Regulation 3 deals specifically with the DGUV test. This section explains the necessary components of a proper inspection. In addition to a visual inspection, this also includes functional tests as well as electrical tests and measurements.

The regulation also emphasizes that these tests must be documented accordingly.

Section 6 of DGUV Regulation 3 regulates work on active parts, i.e. live components of electrical systems and equipment. In most cases, such work may only be carried out if the parts are de-energized. The tension-free state must therefore be established before starting work, unless there are special exceptions.

Good to know

- The German Social Accident Insurance stipulates in DGUV Information 203-071 that inspections should generally be documented.

- The documentation obligation includes a meaningful test report containing the measurement results and measurement procedure.

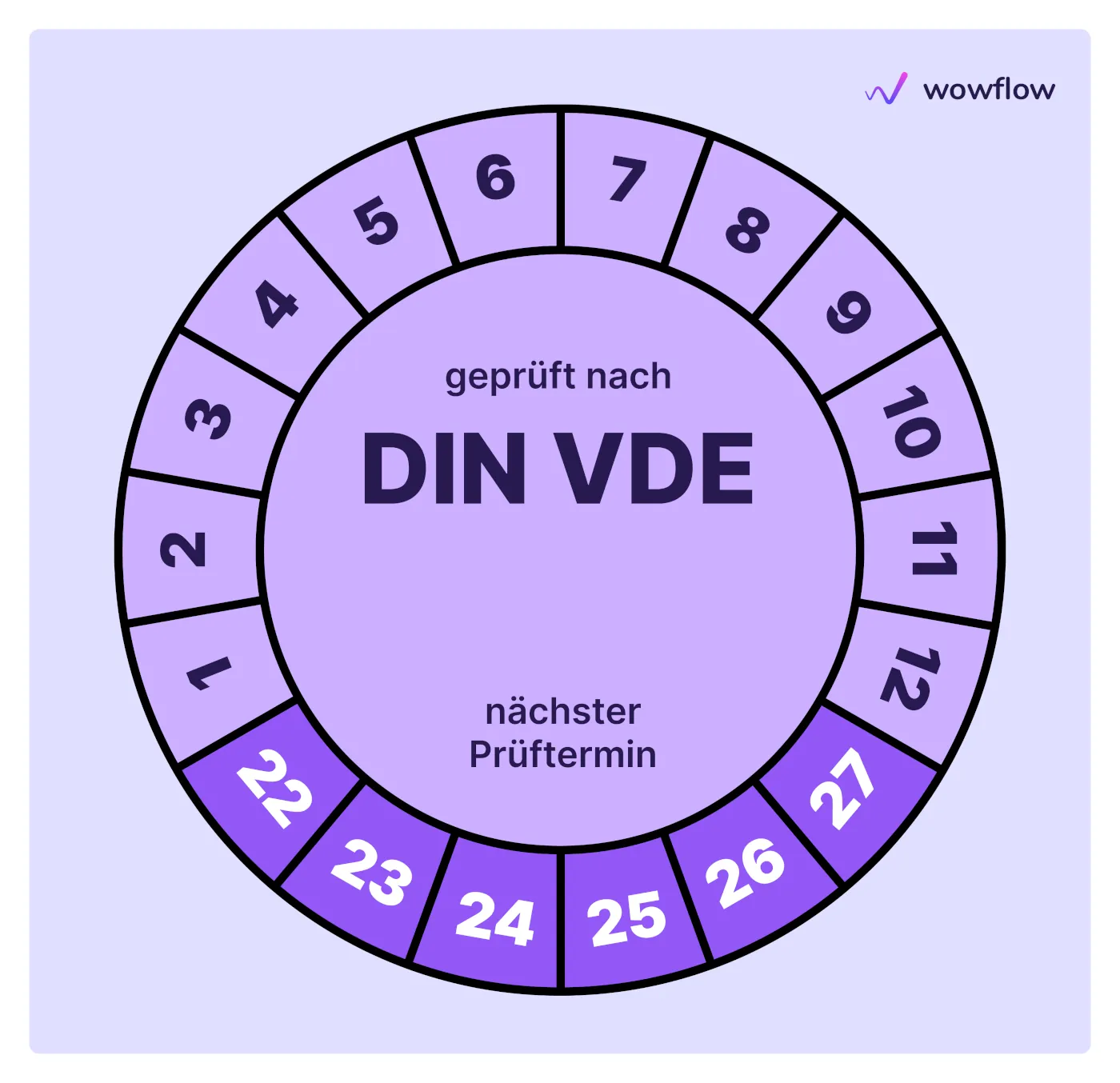

- As a supplementary aid to DGUV Regulation 3, it is recommended that tested devices are marked with a test sticker indicating the date of the next test.

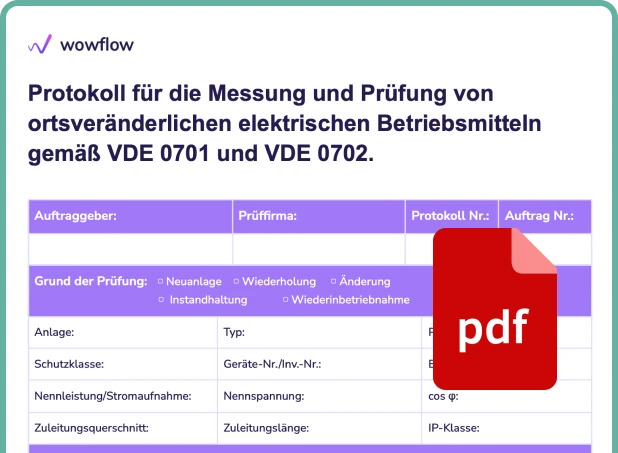

What is a VDE test report?

DGUV Regulation 3 sets out the principles and deadlines for testing electrical systems and equipment. The VDE regulations in turn regulate the specific test details.

The VDE test is an electrical test that aims to ensure electrical safety in companies. It comprises various private standards:

- Testing of electrical devices in accordance with DIN VDE 0701-0702

- Testing of electrical systems in accordance with DIN VDE 0100-600 + 0105-100

- Inspection of shelving in accordance with DIN VDE 15635, taking into account DGUV 108-007

- Testing of care beds in accordance with DIN VDE 0751

- Testing of medical devices in accordance with DIN VDE 0751

- Testing of electrical machines in accordance with DIN VDE 0113-1

The VDE test and the corresponding VDE test report serve as proof for customers that all relevant safety requirements have been met. When the VDE test report is handed over, the customer receives written proof that the test was carried out by qualified specialist personnel and that all legal requirements have been met.

The VDE test is of great importance for occupational safety in companies, as it protects against damage and possible liability claims that could be caused by untested electrical appliances. It is important that the checks are carried out in accordance with the appropriate procedures and measurement methods. We will explain the role of these standards in more detail later in the article .

A brief summary of the main points

The VDE test report is an important tool that is regulated by DGUV Regulation 3 and the corresponding VDE regulations. It proves compliance with safety requirements and plays a decisive role in ensuring electrical safety in companies.

Who fills out test reports?

As previously mentioned, DGUV Regulation 3 stipulates that electrically instructed persons or qualified electricians should be responsible for carrying out the work.

Creating a test report requires specialist knowledge and attention to certain aspects in order to avoid errors. This is the responsibility of persons with technical expertise and knowledge of safety regulations.

Let’s assume that a company operates a hospital. It is the responsibility of the electrician to carry out regular checks of the electrical systems and medical devices and to carefully complete the test report.

Alternatively, companies also have the option of outsourcing electrical tests to external service providers. This is particularly the case when internal resources or expertise are limited.

Through outsourcing, these tasks are handed over to specialized companies such as testing services, which have qualified personnel and the necessary equipment to carry out electrical tests in accordance with the applicable regulations and standards.

What happens if the test report is missing?

If an accident occurs that is directly related to the use of electrical equipment, the liability of the employers’ liability insurance association may not apply if there is no corresponding test report. The insurance company will generally not make any payments beyond this.

In such a case, the company may be faced with considerable claims for damages, especially if the person concerned requires long-term treatment or even becomes unable to work. The company would then be responsible for paying a disability pension, which would normally be paid by the insurance company.

To avoid these consequences, it is very important to fulfill the inspection obligation and to provide written proof of this.

Create and use test report

Find out below what you need to know about creating and using an inspection report to ensure legally compliant and efficient documentation of your inspections.

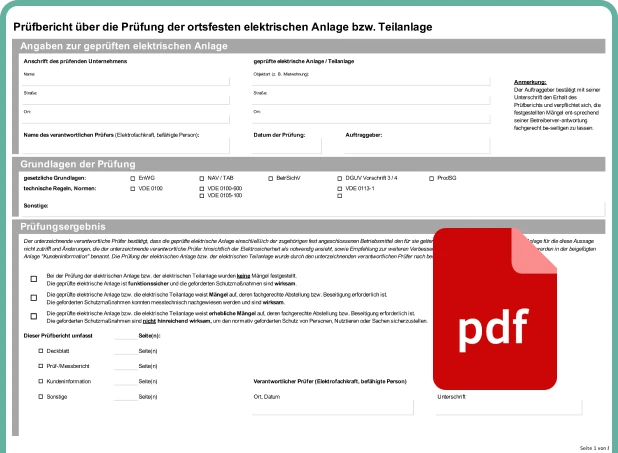

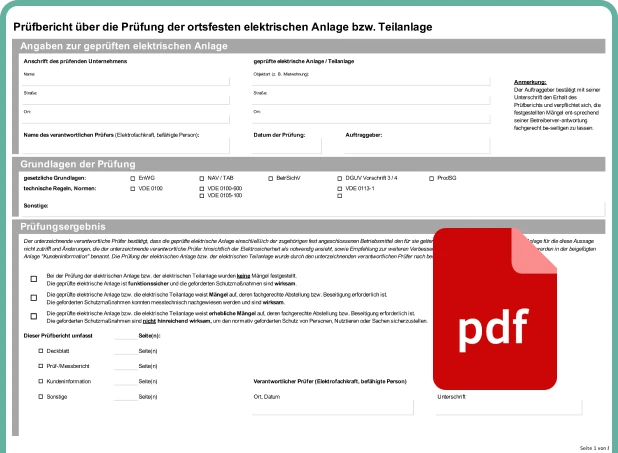

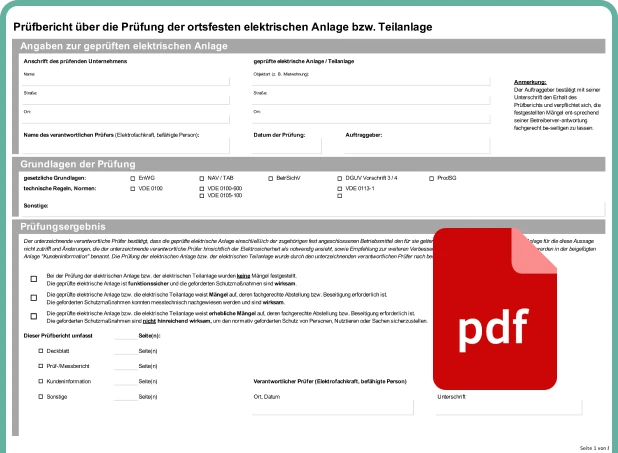

The minimum requirements: What must be included in a test report?

An inspection report in accordance with DGUV Regulation 3 should contain at least the following information:

- Details of the tested electrical system or the tested equipment.

- The basis on which the audit was carried out.

- The result of the test.

- A report on the tests and measurements carried out.

- Details on the individual steps of the test, including visual inspection, functional testing and measurements.

- Customer data and documentation of the defects found.

- Test and/or measuring device used.

Depending on the scope, the description of the individual inspection steps, the defects found and the customer data can cover several pages. The inspection report should be signed by the inspector himself. The creator of electronically created test reports must be indicated.

In general, information on the equipment should include the type, the manufacturer if applicable and the inventory number.

Thanks to modern software, extensive inspection steps, defect descriptions and customer data can be managed efficiently. The integration of photo documentation makes the documentation even more meaningful and can supplement and support the visual inspection.

Request

Complete the test report: 3 tips for comprehensive and meaningful documentation

In addition to the minimum requirements of the DGUV, the test protocols must also comply with the detailed specifications of the VDE regulations.

It is impossible for a template to cover all existing standards and legal requirements. Therefore, the list of possible contents of a test report must be adapted and, if necessary, extended depending on the test object in order to ensure legal effectiveness.

Nevertheless, we have compiled 3 additional best practices that should be included in every protocol:

- Clear information about the electrical devices in operation:

The test report should contain clear and unambiguous information about which electrical devices are present in the business. It is important to distinguish between fixed and mobile devices in order to ensure correct documentation. If the electrical equipment is portable, additional information on the place of use should be noted in the protocol. - Indication of the next test:

It is advisable that each test report and the corresponding final or summary report contain clear information on when the next test should be carried out. This is important to ensure that the inspection deadlines are met and the requirements of the regulations are fulfilled.

On the basis of the risk assessment and taking into account the test results, you can then finally determine the test intervals for individual items of equipment and types of equipment.

These inspection intervals enable future inspectors to obtain a good overview of the overall situation on site and to quickly gain an impression of the inspection results. They ensure that the necessary tests are carried out in good time to guarantee the safety of the electrical systems.

By using software solutions, these inspection dates can be efficiently recorded, monitored and planned. With the help of the software, you can keep track of all upcoming exams and ensure that no deadlines are missed

- Document deviations from test steps in writing:

The tester should be able to independently determine which test steps are applicable and necessary to optimally assess the condition of the system.

If certain test steps are omitted, this must be justified in the test report. It can also be advantageous to comment on certain test results.

Good to know

Fixed installations are generally tested again every 48 months. Portable appliances are normally tested every 12 to 24 months.

However, there are possible differences depending on factors such as the condition of the devices, their frequent use and their specific location and environmental conditions

In the following sections, we will go into more detail about these standards and explain specific test steps for each standard that should be documented in the test report.

We also offer a wide range of templates that are specially tailored to the maintenance of individual systems. You can find all templates here.

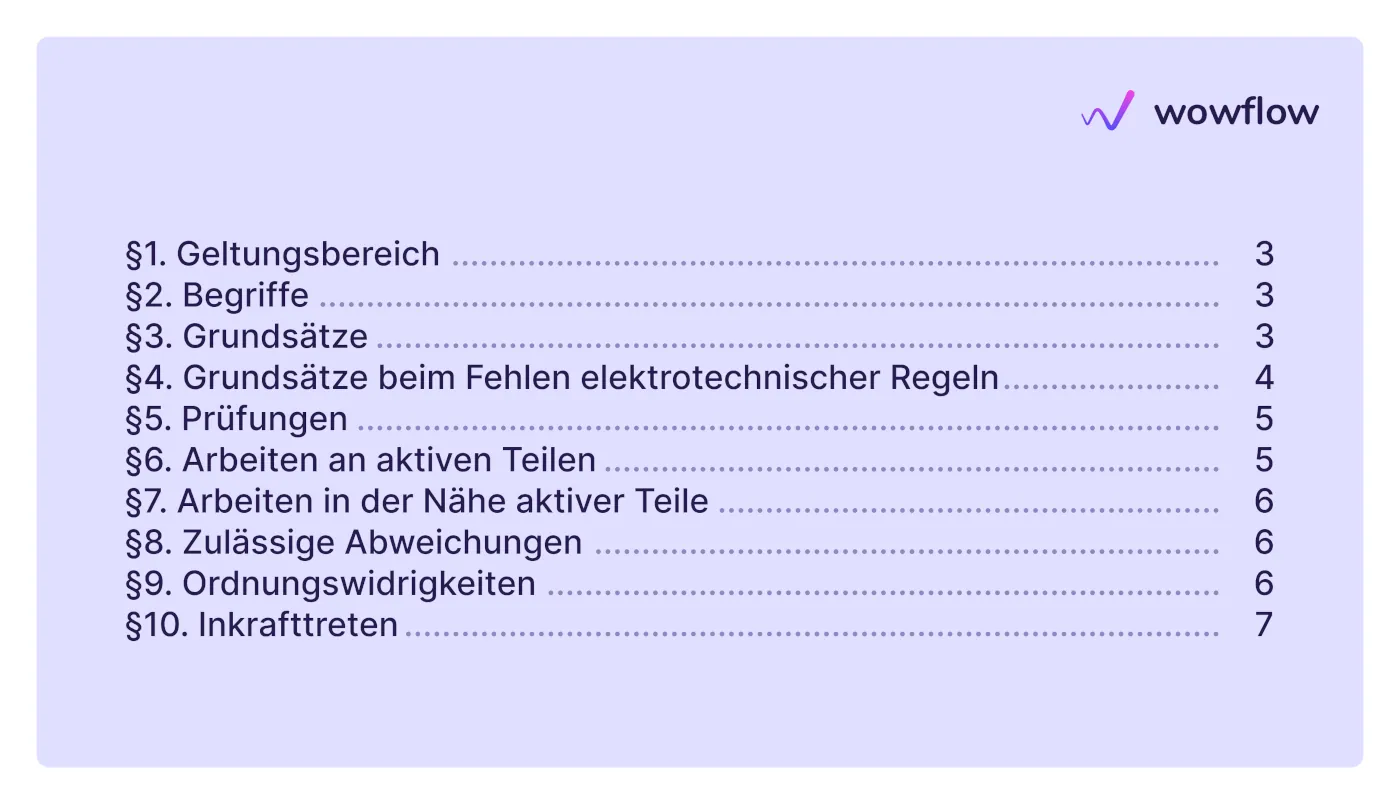

DIN VDE 0100-600 - Initial testing of electrical systems

Area of application:

DIN VDE 0100-600 specifies the requirements for the initial testing of low-voltage electrical installations. This is an inspection that is carried out during construction, after completion of a new system or after modifications or extensions to existing systems before commissioning.

Good to know

Low-voltage electrical installations are generally defined as fixed or mobile installations up to a voltage of 1,000 V (AC) and 1,500 V (DC). These systems are used for the generation, transmission, conversion, distribution and/or application of electrical energy.

Test steps:

During an initial inspection in accordance with DIN VDE 0100-600, a comprehensive visual inspection is carried out during installation to check the condition of the system. The initial test also includes checking the connected equipment and other measures such as testing and measuring (including repeating the test after rectifying faults if necessary).

During an initial test in accordance with DIN VDE 0100-600, the following test steps in particular are emphasized:

- Checking the earth resistance

- Checking the continuity of the protective conductor system

- Checking the insulation resistance of the electrical system

- Checking the voltage polarity and phase sequence

- Checking the effectiveness of the error protection measures

- Checking the effectiveness of the additional protection measures

- Functional tests of equipment, protective and monitoring devices, etc.

- Checking the voltage drop

Request

DIN VDE 0105-100 - Basic standard for electrical engineering

Area of application:

DIN VDE 0105-100 is an important safety standard for all work on, in the vicinity of and the operation of electrical installations at all voltage levels, including extra-high voltage. It applies equally to fixed and mobile installations, both energized and de-energized.

This standard specifies the requirements for safe operation, work and inspections of electrical installations. It requires that the scope and results of the regular inspections are recorded. As a competent person, the tester must also document deviations in measurements or measurement procedures in the test report in accordance with the standard in order to provide sufficient information for future tests, including tests in accordance with other standards.

According to the standard, regular inspections are intended to detect defects that may occur after commissioning and may impair operation or cause hazards. Recurring inspections, including predictive maintenance, also serve to identify hazards caused by changes at an early stage, such as wear and tear, conversions or environmental conditions.

Test steps:

In the test protocol in accordance with DIN VDE 0105 Part 100, various tests are carried out, which include checking the function of protective measures, measuring the insulation, checking the connection of the protective conductor and testing residual current devices.

Request

DIN EN 60204-1 (VDE 0113-1) - Safety of machinery - Electrical equipment of machines

Area of application:

This standard is intended for manufacturers and installers of machines and is aimed at specialists who provide machines with the corresponding electrical equipment. It is comparable to the VDE 0100 series of standards.

Test steps:

Chapter 18 of DIN EN 60204-1 (VDE 0113-1) specifies the following tests for electrical machines:

- Checking that the electrical systems comply with the documentation

- Testing the protective conductor circuits

- Verification of compliance with the conditions for protection by automatic shutdown (where necessary)

- Measurement of the insulation resistance

- Checking the voltage

- Testing the protective devices against residual voltage

- Checking the electrical equipment for additional requirements if earth leakage currents greater than 10 mA occur

- Carrying out functional tests

DIN EN 50678 (VDE 0701), DIN EN 50699 (VDE 0702) and DIN EN 62353 (VDE 0751-1)

Area of application:

- VDE 0701 applies to the testing of appliances after repairs.

- VDE 0702 includes repeat tests.

- DIN EN 62353 (VDE 0751-1) includes periodic tests of medical electrical devices as well as tests after the repair of such devices.

Written or electronic checklists are required for the testing of portable devices and electrical medical devices, as well as marking of the tested object. This can be done through the use of inspection stickers and records, including electronic formats.

Test steps:

Following the revision of the standards DIN VDE 0701-0702 to DIN EN 50678 and DIN EN 50699, the DGUV test is carried out in accordance with the following steps:

- Testing the outer casing of the electrical equipment

- Checking the functionality of the electrical aid

- Measurement of electrical parameters

- Comparison with predefined reference values

- Documentation in a legally usable protocol

- Attachment of an inspection sticker

- Determination of the next inspection date for electrical systems

- Specification of the inventory information of the electrical equipment

- Identification of all potential hazards

- Specification of deadlines and measures to remedy defects

- Signature of the inspector to confirm the inspection of portable electrical equipment

Good to know

The costs for testing portable electrical equipment pay for themselves within just a few months. Since the introduction of DGUV V3 testing, expenditure on new purchases, maintenance and repairs has been reduced by half. Another advantage is that the costs of testing electrical systems are tax-deductible.

Request

Software for digital test reports

The creation of test protocols is associated with many details. This is where a digital solution like Wowflow can effectively support you.

Wowflow offers a user-friendly platform that enables you to create, manage and monitor test protocols efficiently and comprehensively.

See for yourself in the following video how Wowflow helps you to manage your inspection reports effectively and keep track of everything.

Experience for yourself how Wowflow helps you to efficiently create, manage and monitor test protocols –

Get started with Wowflow

Conclusion

The creation and correct use of audit trails is crucial for companies to meet legal requirements, ensure safety and minimize potential liability risks. Test logs serve as complete documentation of tests on systems and devices, provide important information about the condition of the equipment and support compliance with legal regulations.

DGUV Regulation 3 and specific VDE standards define the requirements and test steps for the creation of test protocols. A reliable report should contain all relevant information such as details of the tested system, results of the test, defects found and measurements taken.

Investing in efficient digital solutions such as Wowflow can significantly optimize inspection report management and lead to a long-term increase in efficiency in companies.