A well-managed maintenance log is the key to efficient system monitoring and compliance with facility management standards. This article explains what a maintenance log involves, what the legal requirements are and how you can successfully integrate it into your processes.

Learn how both digital and traditional maintenance protocols can help you minimize downtime and meet regulatory standards.

- A maintenance log documents the condition of a system and is crucial for planning future maintenance and complying with legal regulations.

- The role of the maintenance log in

facility management

is to make maintenance traceable, document defects and increase the efficiency and effectiveness of maintenance. - The digitalization of maintenance logs, including with the help of software solutions such as Wowflow, improves the processing, navigation and security of documentation.

Maintenance log: The basics

A maintenance log is much more than a simple record of activities. It is a comprehensive collection of data that provides information about the condition of your systems and helps to optimize the safety and performance of your buildings.

But what exactly is recorded in such a maintenance log?

Essential components of the protocol

The components of a maintenance log can vary depending on the system and the specific needs of the company. Nevertheless, there is some basic information that should be included in every maintenance log. These include, for example:

- Date and time

- Precise indication of the location or area where the maintenance

maintenance work

took place - Details about the serviced object, e.g. serial number, model, machine

- Type of maintenance work carried out: inspection, repair, replacement of parts, technical inspection, cleaning, etc.

- Information on the condition or problems encountered before maintenance is carried out

- Step-by-step record of the work carried out, including methods and tools used

- List of all components that have been replaced or repaired, including part numbers and manufacturers

- Time spent on maintenance work

- Names and qualifications of the persons or service providers involved in the maintenance.

- Problems or deviations identified

- Information on necessary future repairs or maintenance

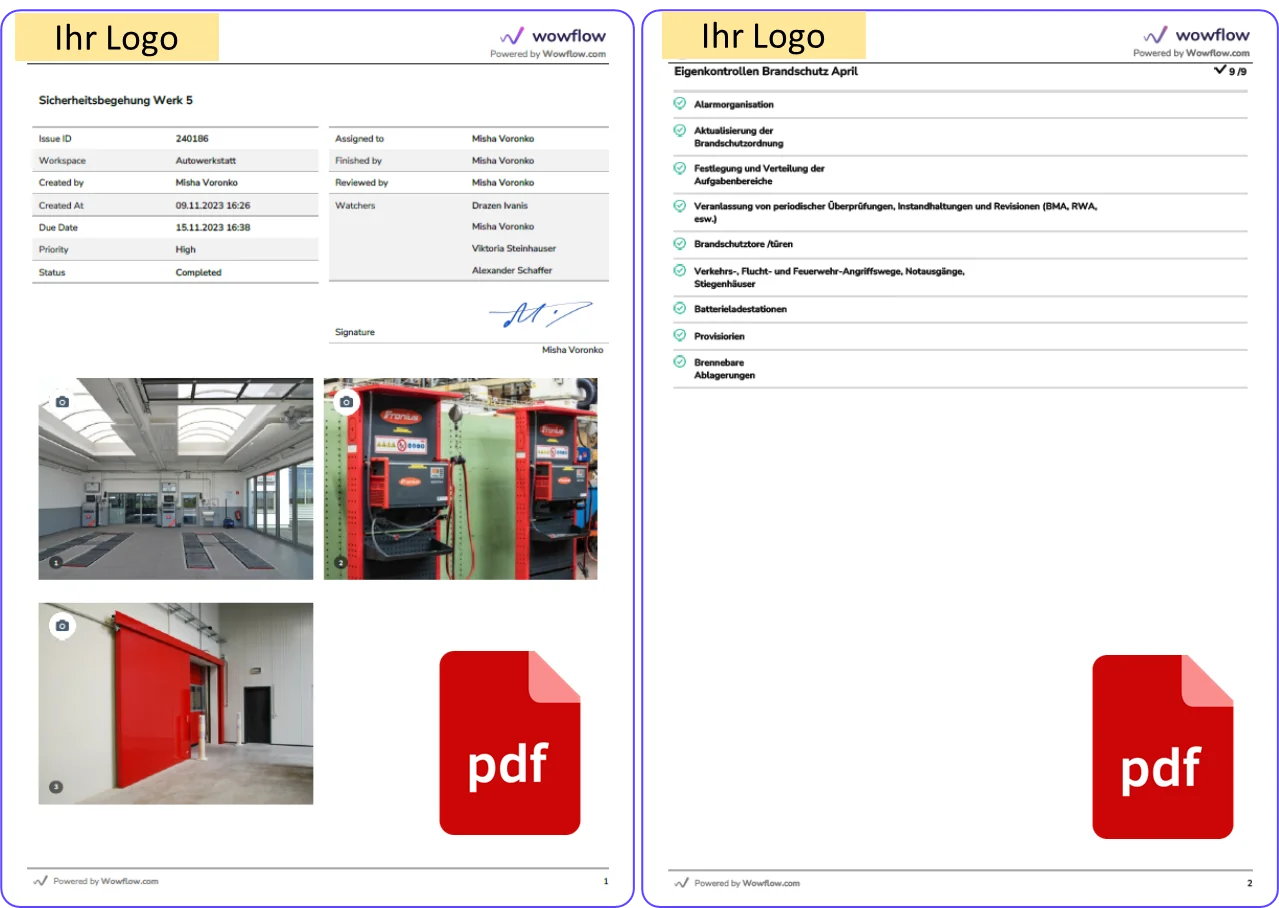

- Release and signature

- Photos or attachments

- List of all materials used with quantities

- Results of safety tests and checks carried out following maintenance

- Proof that maintenance has been carried out in accordance with the relevant statutory regulations and standards.

This information is not only important for the current monitoring of the system, but also crucial for the planning of future maintenance measures.

maintenance measures

.

Legal relevance of maintenance logs

A maintenance log is not only an important tool for optimizing system performance, but is also of great importance from a legal perspective.

It refers to a number of laws and standards such as the Occupational Health and Safety Act, the Product Safety Act and DIN standards. By documenting the maintenance work carried out, companies can prove that they comply with these regulations.

However, if maintenance logs are not kept properly, companies can face legal consequences and fines.

- How well do you know your responsibilities as an operator? Operator responsibility explained!

The role of the maintenance log in facility management

A maintenance log has an important function in facility management. It makes previous maintenance traceable, documents defects and plays a decisive role in improving the efficiency of plant management.

efficiency in plant management

.

It also helps to optimize system performance by:

- enables seamless monitoring and maintenance of the system

- facilitates the identification of recurring problems

- serves as a basis for planning future maintenance work

- ensures compliance with legal regulations and safety standards

By keeping regular maintenance logs, companies can operate their systems more efficiently and minimize downtimes.

Digitize maintenance with Wowflow

The digitization of maintenance logs offers a number of advantages:

- Quick and easy processing via mobile devices

- Elimination of the time-consuming filling out of paper forms

- No subsequent digitization of the logs required

It also enables efficient navigation through interactive checklists and the digital recording and reporting of findings.

Wowflow is an innovative solution that digitizes the maintenance process, offering a range of features such as automatic documentation generation, real-time schedules and maintenance alerts. With Wowflow, companies can professionalize their daily workflows and achieve more efficient work order management.

Simplify your maintenance process from today with Wowflow.

Integration into existing FM systems

The integration of maintenance logs into existing facility management systems such as Computer-Aided Facility Management (

CAFM

) and Computerized Maintenance Management Systems (

CMMS

) is a decisive step towards increasing efficiency and transparency in the maintenance of facilities and buildings.

CAFM systems provide a comprehensive platform for facility management, including space management and real estate management, while CMMS systems are specifically designed to manage maintenance activities.

By digitally recording and storing maintenance logs in these systems, information can be accessed promptly and by authorized users, enabling efficient planning, execution and tracking of maintenance work. The logs can be quickly compared with existing databases to update spare parts inventories, plan future maintenance dates and minimize downtime.

In addition, digital integration supports adherence to compliance guidelines and the generation of detailed reports for internal and external audits. In practice, this facilitates the work of the facility manager, ensures a prolonged service life of the equipment and contributes to improved overall operating efficiency.

- CAFM Software Übersicht: Unsere Marktempfehlungen

CAFM-Systeme bieten eine umfassende Plattform für das Facility Management, einschließlich Raumverwaltung und Immobilienverwaltung, während CMMS Systeme speziell für die Verwaltung von Wartungsaktivitäten entwickelt wurden.

Durch die digitale Erfassung und Speicherung von Wartungsprotokollen in diesen Systemen sind Informationen zeitnah und für autorisierte Nutzer zugänglich, was eine effiziente Planung, Ausführung und Nachverfolgung von Wartungsarbeiten ermöglicht. Die Protokolle können schnell mit bestehenden Datenbanken abgeglichen werden, um Ersatzteilbestände zu aktualisieren, zukünftige Wartungstermine zu planen und Ausfallzeiten zu minimieren.

Darüber hinaus unterstützt die digitale Integration die Einhaltung von Compliance-Richtlinien und die Generierung detaillierter Berichte für interne und externe Auditierungen. In der Praxis erleichtert dies die Arbeit des Facility Managers, gewährleistet eine prolongierte Lebensdauer der Ausrüstung und trägt zu einer verbesserten Gesamtbetriebseffizienz bei.

Wowflow can be used as an add-on or as a CAFM alternative.

Optimization of maintenance processes in facility management

Analyzing maintenance logs can help to improve processes by:

- uncovers defects and their causes

- forms the basis for improving the processes

- plays an important role in preventing machine breakdowns

- provides an overview of all machine costs

Data and properties of the system components and equipment recorded during maintenance are crucial for an efficient maintenance log template.

6 tips for complete documentation in maintenance

Complete documentation in maintenance is important in order to optimize your processes and comply with legal regulations. We have put together 6 tips for you.

1. use a template for an effective maintenance log

A

template for a maintenance log

is an important tool for recording all relevant information and ensuring compliance with regulations. The design of such a form can be optimized by a clear and concise structure, short and understandable labels and instructions as well as easily recognizable input fields and checkboxes.

- Free download of a

smoke detector maintenance log

.

2. personalize your form

Customize your maintenance protocol to meet the requirements of specific maintenance processes and operational standards.

A personalized maintenance form can streamline documentation by providing specific information and instructions for maintenance that meet a company’s individual needs and requirements.

You can customize a standardized form and adapt it to your needs.

Here

you will find our customizable checklists and forms.

3. integrate completion instructions for the form

The correct recording of data in a maintenance log is crucial for the quality and reliability of the documentation. Completion instructions can help to avoid errors or ambiguities in the protocol.

A clear and structured presentation of information, such as the date and time of maintenance, the name of the system/machine and a detailed description of the maintenance work carried out, is essential for effective documentation.

4. ensure correct archiving and access security

The archiving and security of access rights for maintenance logs are important aspects for ensuring the protection of sensitive data and enabling easy tracking of the maintenance history.

Audit-proof archiving of all values on the checklist as well as well thought-out and systematic organization of the documents are required for optimal archiving of maintenance logs.

Your data is safe with Wowflow. No more paperwork!

Access security for maintenance logs can be ensured by measures such as network segmentation or zoning.

5. plan your maintenance & set maintenance intervals

Maintenance planning is an essential aspect of efficient maintenance and contributes significantly to extending the service life of the systems. Effective maintenance is made possible by the use of maintenance plans.

Defining maintenance intervals is a crucial step in ensuring regular inspections. Various factors such as the length of the period, the intensity of use and the condition of the technology must be taken into account when determining the maintenance intervals.

Wowflow offers a calendar function so that you can easily plan your maintenance. Find out more about our

order management software

.

6. log the maintenance steps

Logging the maintenance steps is an essential aspect of the maintenance log. It enables complete documentation and makes it easier to identify potential for improvement.

Manual completion processes often result in errors, which is why we recommend a digital maintenance log.

Summary

In this article, we have highlighted the importance of maintenance logs for plant monitoring, compliance with safety standards and the optimization of maintenance processes. With effective templates and digitized logs, companies can improve their maintenance processes, save costs and extend the service life of their systems.

Regardless of the size and type of your company, a well-managed maintenance log is an indispensable tool for efficient and safe system maintenance.

Use Wowflow to digitize your maintenance log.

Frequently asked questions

What is a maintenance log?

A maintenance log is a document that records all relevant information on the maintenance of machines, installations or systems. It serves as an indicator of the reliability of a system and as a tool for preventive measures and legal protection.

What does a maintenance log say?

Regular maintenance and servicing work for technical systems, equipment or buildings is coordinated and recorded in a maintenance log. Completed work is also noted in order to monitor compliance with the plan.

What does maintenance involve?

Maintenance includes care work, cleaning work, checking settings and recording measured values as well as preventive maintenance measures such as lubricating, adjusting and refilling operating materials.

Why is maintenance important?

Maintenance is important to restore the system to its target condition and to delay or prevent the progression of wear and tear. This allows the system to be operated efficiently and safely.