Discover the benefits of CMMS software and how it optimizes your maintenance processes. From seamless integration into your operations to increasing plant performance, CMMS systems offer a digital solution to make your maintenance effective.

Learn how companies successfully implement CMMS and what best practices will help you improve your operations. Step into the future of maintenance technology and revolutionize your company with CMMS!

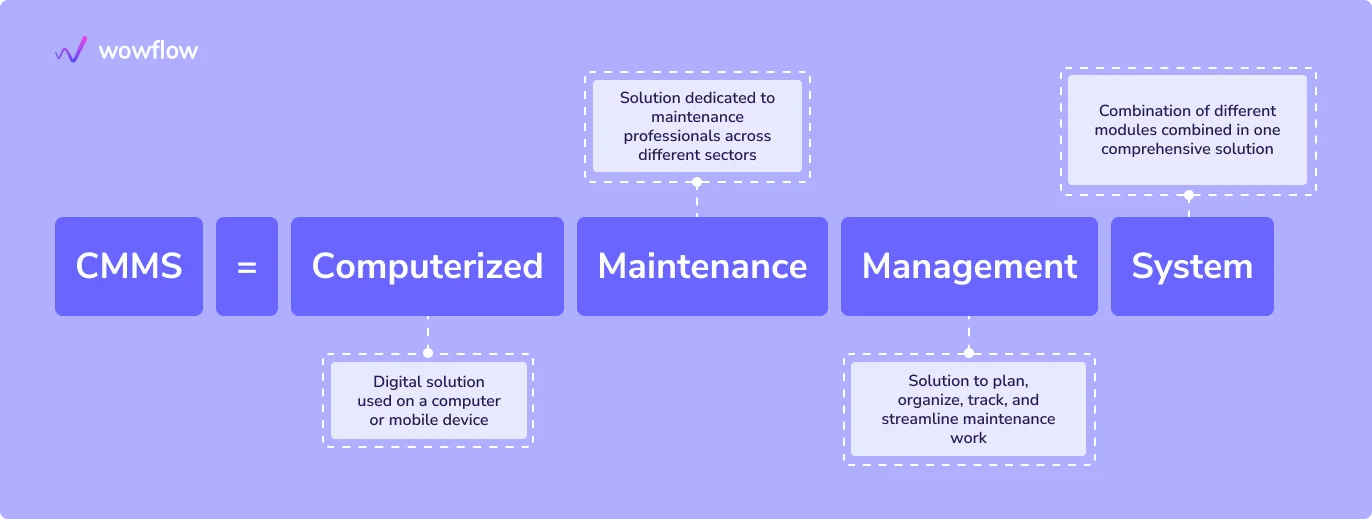

What is a CMMS?

CMMS stands for “Computerized Maintenance Management System”. There are different names for a CMMS, such as CMMS software, CMMS system, CMMS platform, CMMS solution or maintenance management software.

They all refer to the same thing: software that is used to manage the maintenance and servicing of systems.

CMMS helps in facilities management with planning, execution and monitoring of maintenance tasks, the management of equipment and the documentation of maintenance activities.

With CMMS software you manage:

- Production facilities

- Maintenance personnel

- Inventory for maintenance, repair and

- Operation

- Delivery vehicles

- Production plants

- Storage facilities

- CAFM: Management software for efficiency in facility management

How does a CMMS work?

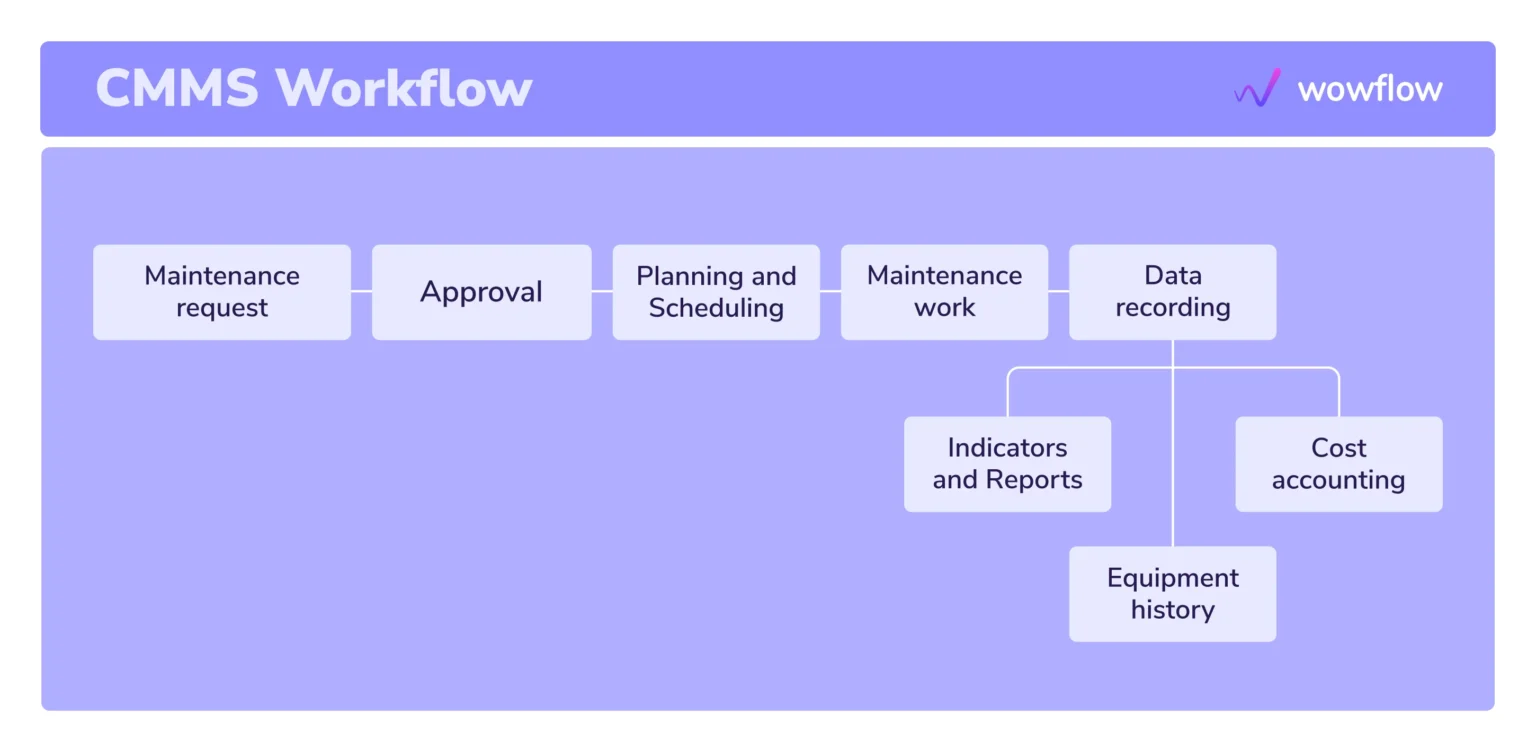

A CMMS system is all about work orders. They can be tracked, edited, marked as completed, archived and used to create detailed reports in real time.

For example, if your preventive maintenance schedule includes multiple tasks in the HVAC system, you only need to create one maintenance request, such as filter changes, schedule it for a specific date and time and assign it to a technician.

As soon as the technician has completed the task, he marks it as “completed” and has one less task on his (and your) list. This is the main purpose of any maintenance management software. This process applies to both reactive maintenance (or corrective maintenance) and preventive maintenance.

The most important functions of CMMS

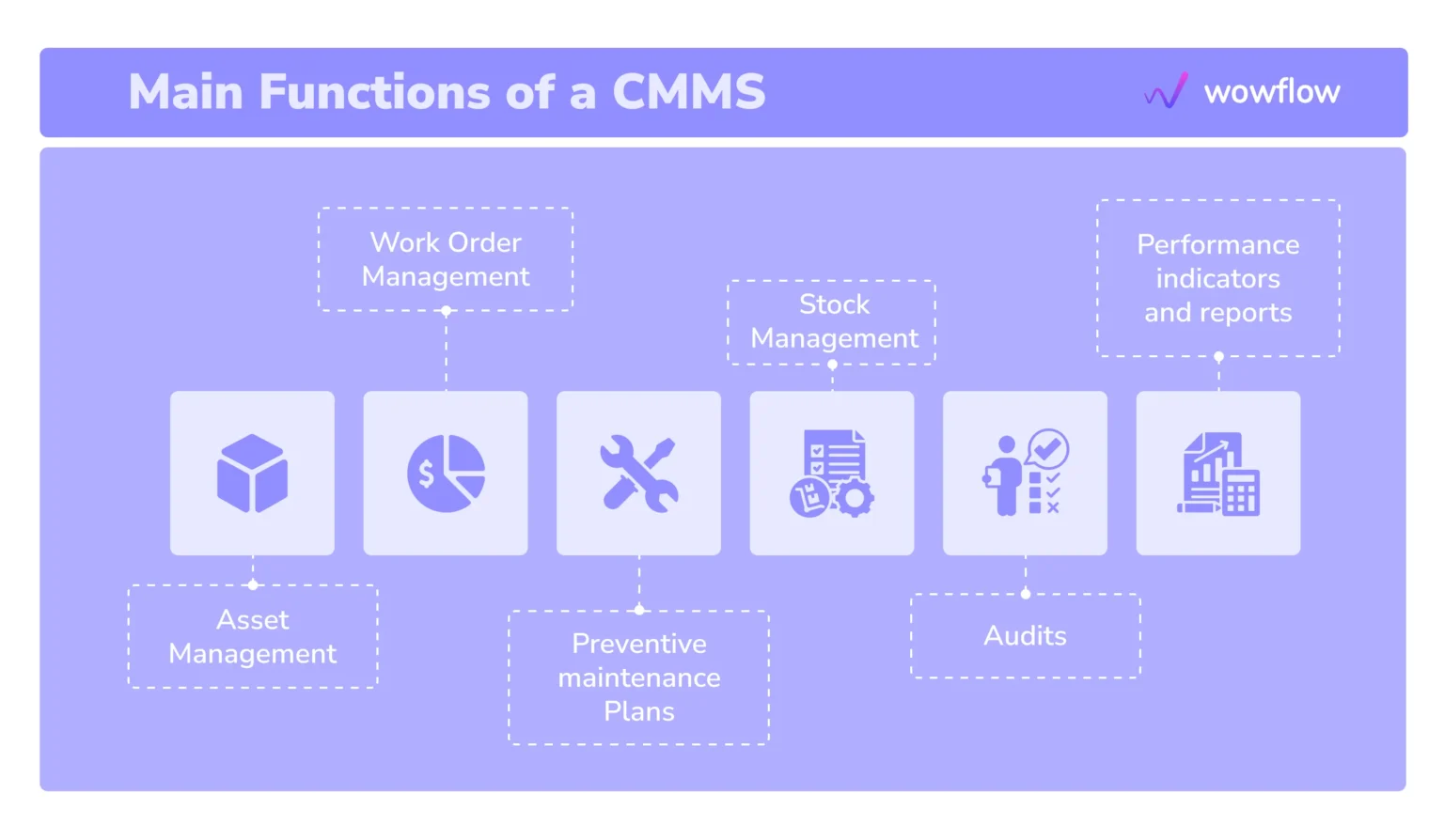

In addition to the management of work orders, the other functions vary depending on which CMMS you use in your company. However, the main task of CMMS software is to speed up the management of maintenance requests, simplify communication and improve control over all maintenance work.

Here are some examples of the most important functions of CMMS:

- Asset management so that you can access all asset information about the individual devices at any time.

- Task scheduling and preventive maintenance and servicing features to help you plan routine inspections.

- Mobile CMMS app for maintenance teams, service providers and other employees.

Today, a CMMS should definitely offer mobile access. With Wowflow’s mobile app, you’ll never lose track of your work orders again.

Find out more about our order management software!

Error reports and reactive maintenance functions to resolve unexpected device failures.

Warehouse management to control the inventory and avoid disruptions in the warehouse.

Creation of maintenance requests from any employee or customer, enabling faster fault detection.

Conducting audits for your systems and infrastructures.

Monitoring energy consumption, e.g. of water, gas and light in your buildings.

performance reports, because there is always room for better maintenance strategies.

Integrations: Modern CMMS software can be integrated into other applications.

Wowflow ensures to offer the perfect end-to-end solution through its compatibility with leading software solutions.

Find out more about the innovative products from Wowflow! Book a demo here!

Who uses CMMS software?

CMMS is suitable for anyone involved in the maintenance of a company or organization with many assets and a complex physical infrastructure.

CMMS software helps these teams to optimize their maintenance management. These interest groups include, for example:

- Maintenance manager

- Maintenance and repair technician

- Inventory manager

- IT personnel

- Facility Manager

- Production teams

- Executives

- Safety assessor

- Service providers

Overview of CMMS benefits

CMMS software has numerous benefits that can lead to significant money and energy savings, as well as a safe environment and overall operational efficiencies:

Unplanned downtime: why you must avoid it at all costs

The cost of unplanned downtime for large manufacturing and industrial companies has risen dramatically since 2020.

One hour of unplanned downtime costs manufacturers at least 50% more today than in 2019-2020.

In 2021, downtime in the automotive industry induced costs of 2 million euros per hour.

To keep downtimes to a minimum, we recommend the use of CMMS software

Focus on the 6 most important CMMS benefits

CMMS systems have great potential. We have selected the most important advantages for you that will enable your company to operate efficiently – regardless of the industry sector.

1. Overcome the maintenance backlog with CMMS

The maintenance backlog is the accumulation of pending or deferred maintenance work that has not yet been completed.

A certain amount of maintenance backlog is unavoidable. However, with a large maintenance backlog, it is only a matter of time before you are confronted with a growing number of faults, device failures and high downtimes.

The cost of backlogged maintenance work in US national parks is estimated at 12 billion dollars. This is an extreme case, but it shows how important it is to keep the maintenance backlog at an acceptable level.

A CMMS ensures a balance between resources and maintenance costs so that the backlog does not get out of control. The software records small repairs that would otherwise go unnoticed and allows maintenance tasks to be planned, assigned and prioritized so that no tasks fall through the cracks.

2. CMMS to extend the service life of your systems

As it is not always financially feasible to replace old systems with new ones, professional maintenance is crucial.

To keep the appliances in good working order for longer, they need to be serviced before something breaks. This cannot be achieved with OEM guidelines or assumptions.

Sensors can detect wear, temperature or vibration and can be attached to the various systems.

You can use the sensor data to determine when and what preventive or corrective measures should be taken.

The integration of CMMS software with sensors allows you to track the condition of a system in real time, detect failures before they occur, diagnose problems and schedule maintenance.

3. Energy saving with CMMS

Well-maintained systems are more energy efficient and the key to reducing your overall energy costs.

Reactive maintenance is one of the main causes of energy waste in production plants, as it leads to inventory problems and poor planning, among other things.

A CMMS solves these problems and ensures better preventive maintenance, especially with tools such as automated work orders and simple order management.

4. accurate prediction of the materials you need for maintenance

If you don’t have a handle on your inventory, it can lead to all sorts of costly problems. Excessive expenditure on stock can increase the original purchasing costs by a further 12 % to 20 %.

If you don’t have the right parts in stock (or can’t find the parts in a messy storeroom) when an appliance breaks down, it leads to downtime, rush shipping and risky workarounds, all of which are expensive.

Managing your inventory with a CMMS helps you procure, track and organize materials so you can avoid costly problems.

Features such as automated purchasing, inventory reporting and AI-powered spare parts forecasting can help you make data-driven inventory decisions and avoid overstocking and understocking.

5. CMMS ensures a safe working environment

A CMMS facilitates order management that takes the well-being of the teams into account. You can add checklists, safety data sheets, safety measures and required protective equipment so that you can be sure that the technicians carry out their work safely and avoid risks.

CMMS contributes to a better awareness of safety issues in the maintenance teams.

Safety measures can be made more accessible and visible on checklists and system profiles. Technicians can call these up on their phone at lightning speed so that they don’t miss any important safety instructions.

In this way, the employees in your company remain unharmed.

With Wowflow’s software for workforce scheduling you can manage your employees efficiently and clearly.

6. Faster repairs and inspections

Downtime always occurs when a system needs to be repaired or inspected. However, if repairs and maintenance work are inefficient, the downtime is extended. These inefficiencies can cost your company a lot of time and money due to production downtime.

A CMMS facilitates the repair and inspection of systems and reduces downtimes to a minimum. Technicians can log into a CMMS mobile app from anywhere and view a system’s history, diagrams, the location of spare parts, so the job can be done faster.

CMMS software can also help you find work orders that are taking too long, identify the cause of the delay and fix it so the work can get done faster.

Wowflow understands the importance of smooth workflows. With its intuitive collaboration platform, Wowflow guarantees access to all parties involved, including external service providers.

Are you looking for a tool for facility management collaboration?

Test our Start package out for free!

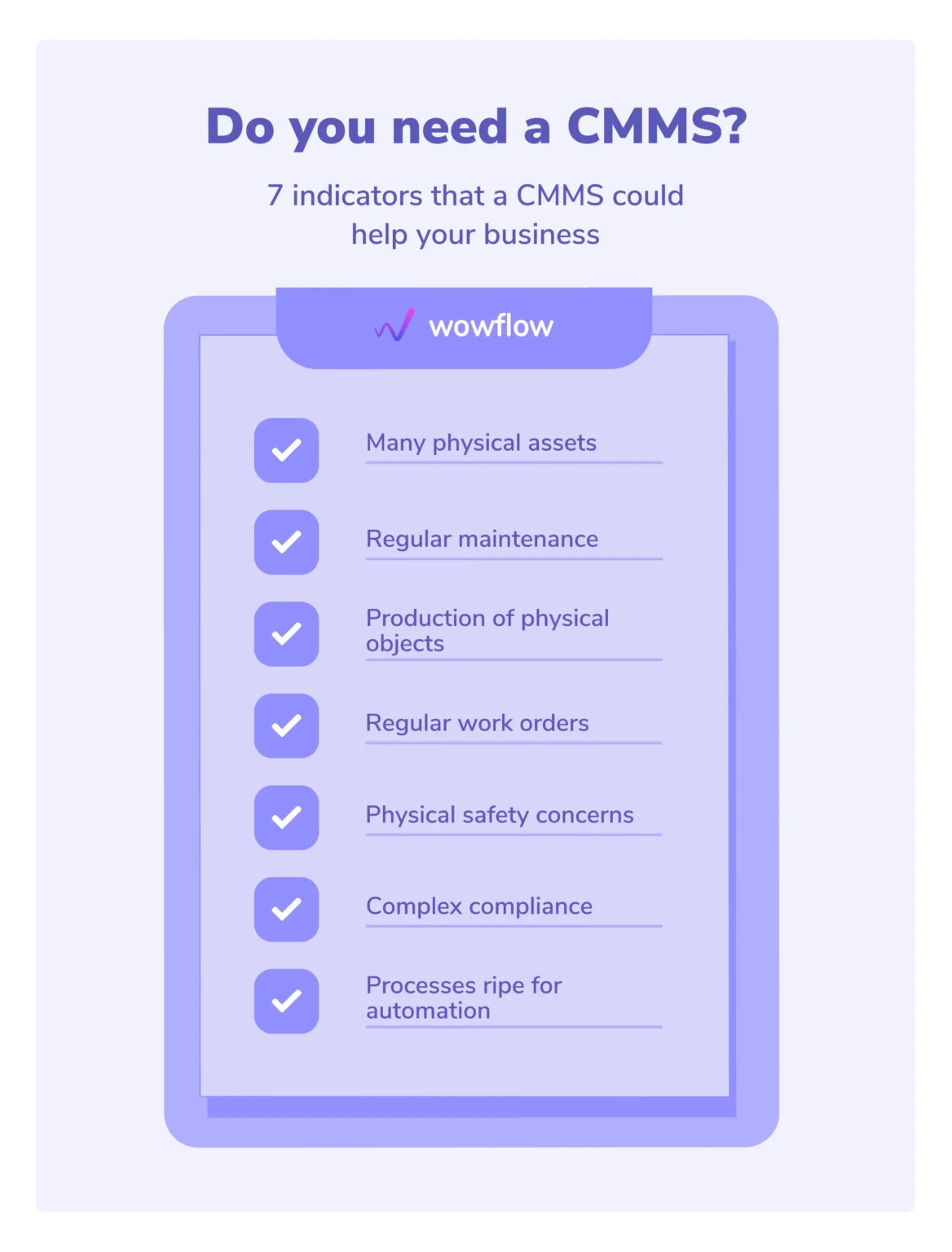

Do you need a CMMS?

We have prepared a checklist for you to help you make the right decision for your company:

If you have ticked most of the boxes, you should consider a CMMS – or even an EAM if the complexity is even greater than for maintenance.

Find the perfect CMMS software for your company

Pay attention to these 7 key functions to find the right CMMS for your company.

1. Configurability and integration: The best solution is tailored to your individual needs. The software should integrate seamlessly into your existing workflows. It grows with you over time.

2. Training and professional services: Find a partner who can support you with training, implementation, support and long-term professional services.

We offer customized onboarding for our order management software: you can get started in just a few minutes.

3. User-friendliness: This is crucial for software, especially if it is intended to make your work easier. Navigation and finding information should be simple and intuitive.

4. Mobile order management software: order management is carried out in real time. It is immediately available to your team, no matter where they are

5. Reporting and forecasting capabilities: What kind of maintenance reporting and forecasting does your team need, and can the software fulfill these requirements

6. Automation functions: Robust automation functions are essential for CMMS.

Last but not least, the overall costs associated with implementing a CMMS solution should also be carefully examined.

We have identified 4 factors that can affect the total cost of a CMMS solution:

1. Scope of service: As CMMS can be scaled to meet individual functional requirements, this can be one of the biggest factors in software costs.

For smaller companies and infrastructures with moderate complexity, software in the lower category may be sufficient. More robust offerings can drive up costs quite quickly, but can also lead to huge cost savings.

Wowflow is suitable for small and medium-sized facility management teams. We offer you exactly the right functions to support your day-to-day business.

Start here for free!

2. Size of the company: If you want to implement a CMMS for a large team with many users, many assets and dynamic authorization and access requirements, you can assume that this complexity will be reflected in the product costs.

3. Implementation costs: setup, training, integration and possible downtime during installation can be associated with costs.

4. Popularity of the software provider: With CMMS, you may pay a premium for larger software providers. This is the price they pay for their good reputation, which sometimes extends beyond the CMMS industry.

You may be able to keep costs down by choosing software from newer or smaller companies. We recommend that you always check the ratings and available functions carefully.

Wowflow ensures that the implementation process remains as efficient as possible.

Start here for free!

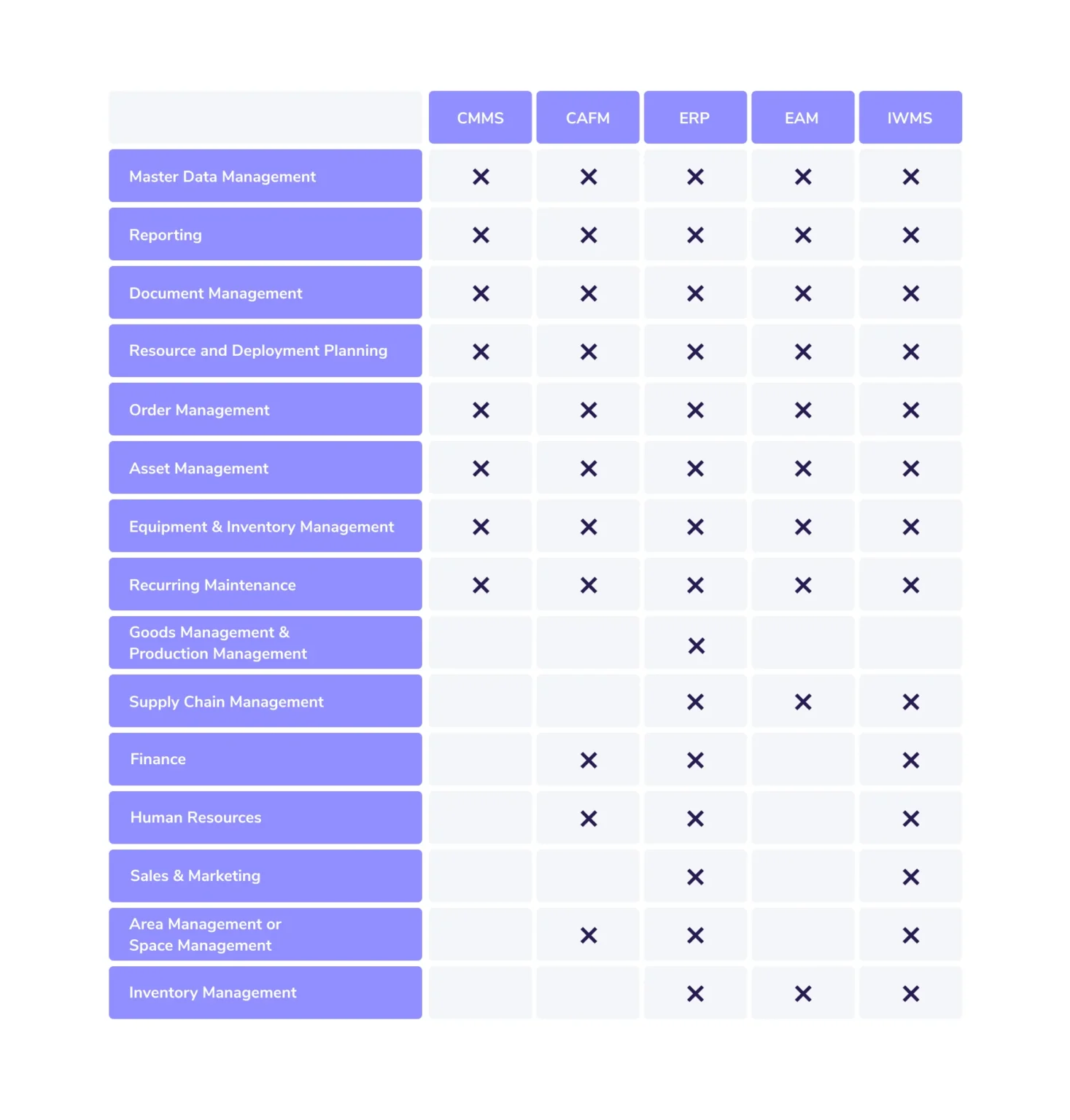

Software solutions in comparison: What is the difference between CMMS, CAFM, ERP and EAM?

In addition to CMMS, there are other possible technologies that can increase the efficiency of your company.

CAFM vs. CMMS

CAFM refers to Computer Aided Facilities Management software. With CAFM software, you can manage the physical workplace and everything in it. In addition to creating floor plans, it also ensures optimal use of space.

A CAFM provides information for facility managers and external service providers. This information includes:

- the utilization of office space

- cleaning cycles

- maintenance and servicing specifications

- the mapping of the entire building technology

The difference: a CAFM is static and a CMMS is dynamic. All information about the property is stored in the CAFM. Figuratively speaking, it can be compared to a large library containing data instead of books.

The CMMS software database, on the other hand, contains information on the operational activities that support the maintenance of the building.

CMMS vs. ERP

ERP means Enterprise Resource Planning. An ERP system is an application that supports a company’s resource planning. In this case, the term resources includes personnel, capital, operating resources, materials and information technology.

CMMS systems are used for maintenance and servicing. An ERP system, on the other hand, can be used in various industries. Typical functional areas are as follows:

- Finance and accounting

- Human resources

- Marketing and sales

- Document management

- Merchandise management

- Determination of requirements

The ERP system is very comprehensive and is usually made up of application modules that are combined with each other. A CMMS is usually not split into subsystems.

CMMS vs. EAM

EAM or Enterprise Asset Management is a combination of services, systems and software for asset management. EAM includes: maintenance, order management, resource planning and scheduling, supply chain management and initiatives for environmental, health and safety at work.

EAM systems have the task of optimizing the entire life cycle of the systems in the company.

An ERP offers a comprehensive range of functions, while the CMMS only focuses on centralizing information to optimize maintenance strategies.

While the EAM system attempts to optimize each individual “life cycle stage”, the CMMS focuses on the maintenance and servicing of buildings, equipment and systems.

In smaller companies, the sole use of a CMMS is usually sufficient, as it is significantly cheaper than the EAM system.

Wowflow can meet the exact needs of medium and small companies and offers an easy-to-implement alternative to traditional CAFM or EAM software.

Efficient facility management with the intuitive software solution from Wowflow.

Book a demo here!

Your advantages with Wowflow:

Compared to CMMS, Wowflow’s solution is specifically tailored to the needs of facility management teams. Our software supports your specific challenges in maintaining your buildings and systems, regardless of the size of your company.

Too many software functions can make work more difficult. That’s why Wowflow offers a simple solution to make work easier, collaborate as a team, manage orders and manage assets.

It’s as simple as that:

Free demo: Test the product before you invest.

Fast set-up process: With personal onboarding, we ensure that you can get started within a week.

Multi-collaboration: Work with external service providers, even if they do not have a Wowflow account.

Intuitive interface: user-friendly environment with exactly the modules your teams need.

Integration: Stay connected to your standard ERP or CAFM tools. Simply supplement your existing CAFM with the Wowflow add-ons. Select exactly the functions you need.

Frequently asked questions about CMMS

What does Saas and on-premise mean?

SaaS is a cloud-based solution: the software is hosted and managed centrally by the service provider. With on-premise, the software is installed and operated locally.

CMMS software: Saas or on-premise?

SaaS offers greater scalability, accessibility and easy updates. The on-premise solution offers more control and customization options, but requires higher investment costs and IT resources.

What is IoT?

IoT stands for the Internet of Things and refers to the networking of physical devices and objects that communicate with each other and exchange data via the internet. The more data is connected to your system, the better it can prevent system failures.

Which areas of application make sense?

Useful areas of application are maintenance & repair, quality control, field service, audit management, occupational health & safety.