Ensure efficiency and avoid breakdowns: Maintaining your heat pump is essential. What measures are part of heat pump maintenance and how often is it necessary? This guide shows you what really matters.

You can also use our Checklist for heat pump maintenance.

- The maintenance of heat pumps differs depending on the type and includes specific measures to maximize effectiveness and efficiency and ensure the longevity of the system.

- Regular maintenance includes general measures such as checking and cleaning the refrigerant circuit and mechanical components, as well as optimum adjustment of the control system for efficient performance.

- Professional maintenance is recommended at least every two years, at a cost of between 150 and 350 euros per year; self-maintenance involves risks and can affect warranty claims and insurance cover.

Heat pump maintenance: Different heat pump types

There are different types of heat pumps, including air-to-water heat pumps, brine-to-water heat pumps and water-to-water heat pumps. Each heat pump has specific maintenance requirements to ensure optimum performance and efficiency.

Here you can find all of our checklists for facilities management.

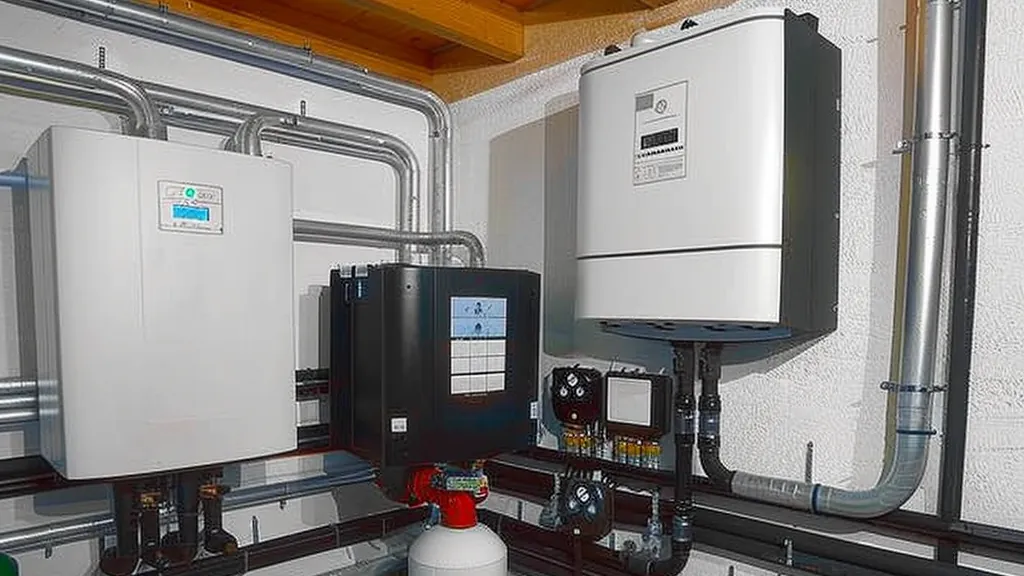

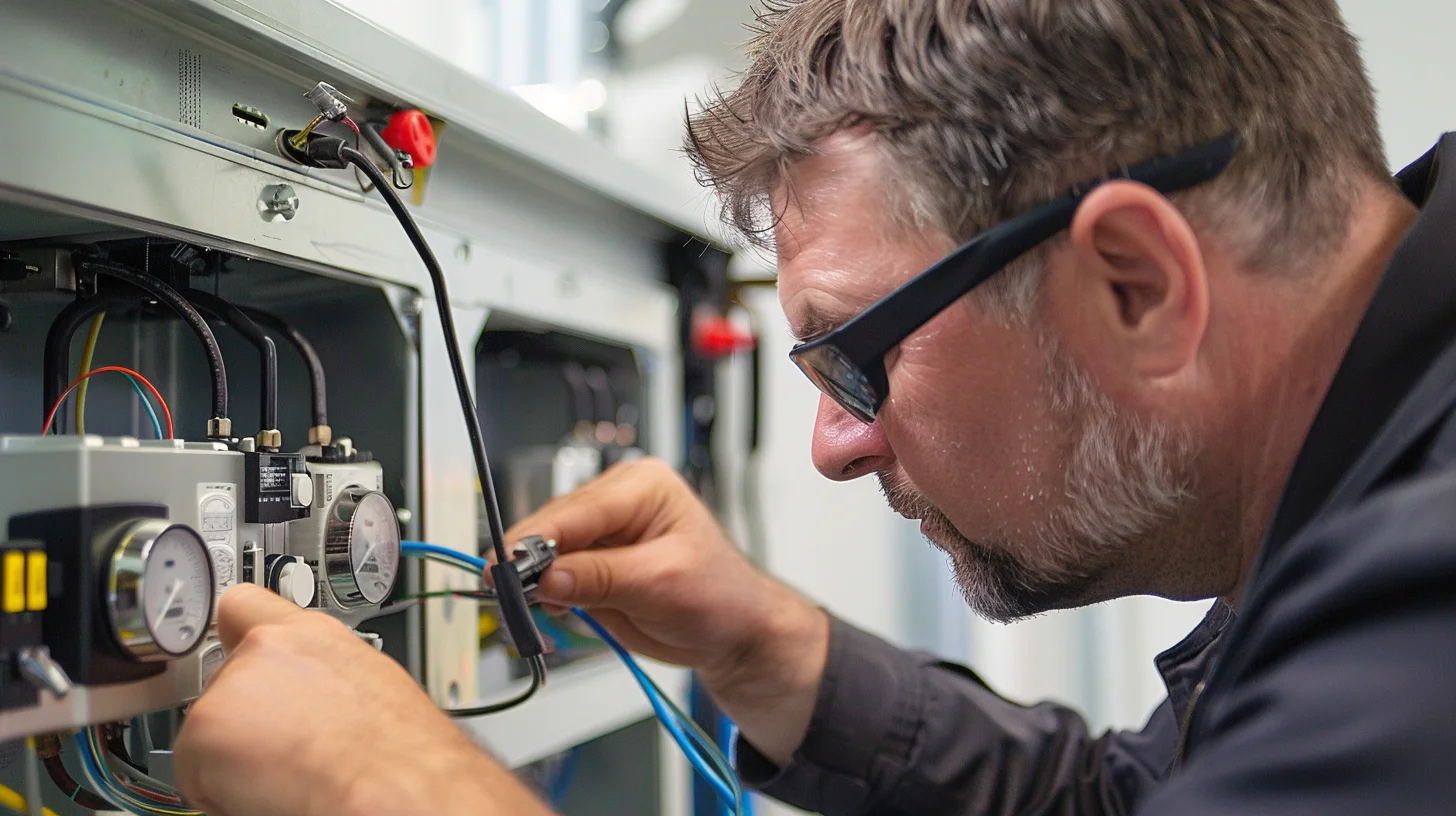

Heat pumps require regular maintenance to ensure their longevity.

In the following sections, we will describe the specific maintenance measures for each of these heat pumps in detail.

Air-to-water heat pump

An air-to-water heat pump uses the ambient air as a heat source. The following measures are essential to ensure effective operation:

- Careful inspection and cleaning of the air openings and fans

- Checking the supply air and exhaust air ducts

- Cleaning the vaporizer

- Monitoring the development of condensation

- Ensuring optimum condensate drainage performance

Another important aspect of maintaining an air-to-water heat pump is checking and inspecting the refrigerant line. Correct refrigerant piping is crucial for the efficiency and safety of the system. It should therefore be checked carefully during maintenance and any problems that arise should be rectified immediately.

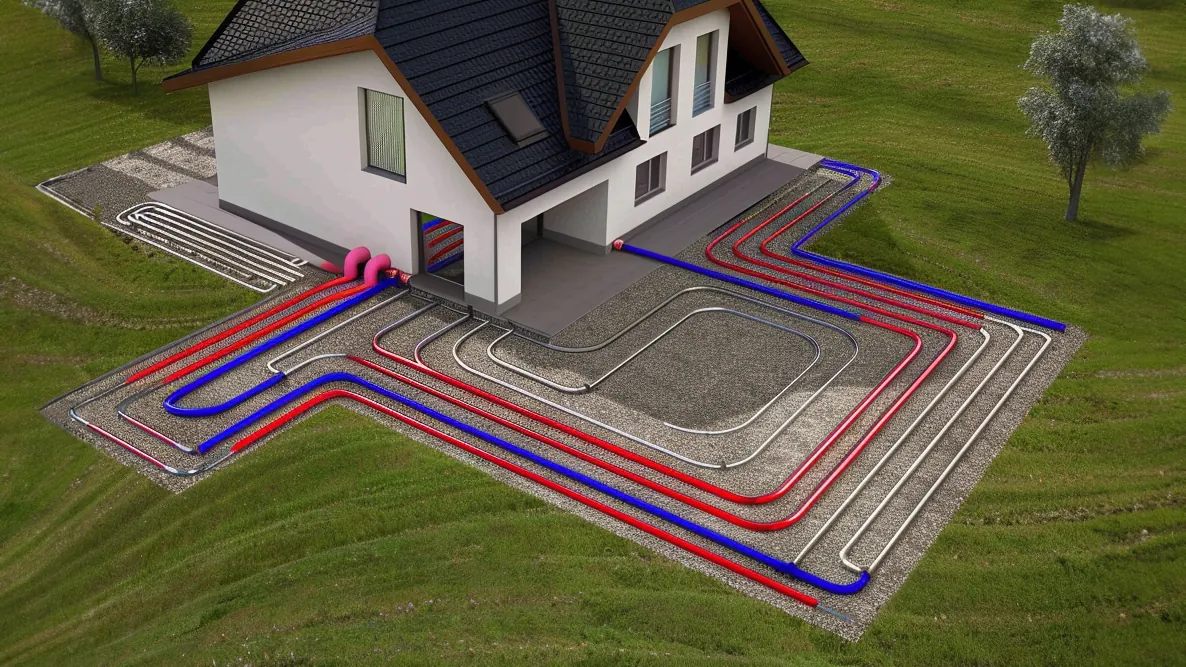

Brine-to-water heat pump

The brine-to-water heat pump uses the ground as a heat source and provides hot water for your home. The chemical composition of the brine must therefore be checked during maintenance to ensure adequate frost protection. In addition, checking the filter in the heat circuit is an integral part of maintenance. This must be cleaned if necessary to ensure efficient heat transfer.

Another important aspect of brine-to-water heat pump maintenance is measuring the pressure conditions in the system. If the pressure is too low, brine must be topped up to ensure that the heat pump functions correctly. The pressure conditions should therefore be carefully monitored during maintenance.

Water-to-water heat pump

The water-to-water heat pump uses groundwater as a heat source. It is therefore important to check the wells regularly to ensure that they are working effectively and pumping the groundwater correctly. In addition, the mechanical components, such as pumps, valves and filters, must be subjected to close inspection to ensure that the water-to-water heat pumps function properly.

A regular visual inspection for water contamination in the well is also important. The quality of the groundwater is crucial for the performance and safety of the heat pump. Therefore, such checks should be carried out regularly and any contamination should be removed immediately.

Heat pump maintenance: General measures

Regardless of the type of heat pump, there are a number of general maintenance measures that are relevant for all types of heat pumps. This includes:

- Checking and cleaning the fluid circuit

- Checking and cleaning the electrical system

- Checking and cleaning the valves and filters

- the control of pressure and temperature.

We will explain these measures in detail in the following sections.

Liquid circuit

The refrigerant circuit is a central component of the heat pump and is crucial to its efficiency. It is therefore essential to ensure a constant flow of refrigerant and to identify and eliminate air in the system or contamination of the refrigerant.

Signs of air or irregularities in the flow of refrigerant must be checked as they could indicate a possible leak. Furthermore, an annual leak test is mandatory for heat pumps with more than three kilograms of refrigerant to ensure the integrity of the system. This work should only be carried out by certified specialists in order to treat leaks or flow deviations professionally.

- Operator responsibility in facilities management

- Your guide to effective servicing

- Create productive workplaces with facilities management.

- These are the most important janitor activities

Mechanical components

The mechanical components of a heat pump, such as compressors, safety valves and circulation pumps, must be carefully checked during maintenance. Once a year, the expansion vessel should be checked for proper functioning and the filter and dirt trap of the heating circuit should be cleaned to ensure optimum performance of the system.

Regular inspection of these components is important as they are exposed to high loads. Early detection of problems enables them to be rectified in good time and prevents costly repairs or breakdowns.

Control of the heat pump

The efficiency and cost-effectiveness of the heat pump depend to a large extent on the correct setting of the control unit. Regular checking of the controller settings, including reading out the fault memory and checking the operating data, ensures efficient operation of the heat pump.

Optimum adjustment of the heating curve in terms of base point and slope is crucial to ensure that the heat pump runs as efficiently as possible. A control system that is not set optimally can prevent the heat pump from working at full capacity, which in turn can lead to higher heating costs.

Frequency of heat pump maintenance

Most manufacturers recommend servicing the heat pump at least every two years, although the trend is towards an annual check. Adjusting the maintenance intervals is usually linked to the manufacturer’s specifications and can be looked up in the technical documentation.

There are no statutory maintenance intervals for heat pumps, apart from the annual leak test for systems with a refrigerant circuit containing more than three kilograms of refrigerant. Regardless of legal obligations, experts and manufacturers recommend annual maintenance for reasons of longevity and to prevent damage.

The ideal frequency for maintenance varies between annually and every three years, depending on specific factors such as the type of heat pump and its operating time, as well as the quality of the system.

Heat pump maintenance: these are the costs you will incur

The average cost of maintaining a heat pump in a normal detached house is between 150 and 350 euros per year, depending on the work carried out and its scope. Maintenance contracts usually vary depending on the provider, with annual costs often around 300 euros and can include services such as fixed maintenance intervals, reminder maintenance appointments and priority service.

In addition to standard maintenance work, maintenance contracts often offer optional services such as remote monitoring, which can provide additional security. It is important to note that the maintenance effort and costs are usually significantly lower than the costs that can arise from the failure or inefficient performance of an unmaintained heat pump.

Self-maintenance of heat pumps: possibilities and risks

Self-maintenance of heat pumps can appear attractive at first glance, as it may seem more cost-effective. However, it is important to note that this approach is associated with considerable risks.

Work on the refrigeration circuit and other specialized activities may only be carried out by persons with a certificate of competence. Regular maintenance work by a specialist company can also be a prerequisite for warranty claims against the manufacturer, and self-maintenance can lead to a loss of these claims.

Insufficient knowledge of the refrigerant system can lead to a loss of refrigerant, which can cause environmental damage and significant losses in heat pump efficiency. Improper actions during self-maintenance can lead to malfunctions, loss of performance and, in the worst case, to considerable damage. It is therefore important to familiarize yourself with the heat distribution system of the heat pump.

In addition, maintenance work carried out by the system operator without specialist knowledge can lead to the loss of insurance cover. Therefore, using a professional maintenance service can be both safer and more cost-effective in the long run.

Tips for the effective maintenance of a heat pump

Regular maintenance of heat pumps is crucial for the safety of operation and the financial and ecological benefits. Ideally, maintenance should be carried out in the summer months to minimize the likelihood of breakdowns in the winter months when the heat pump is needed most.

Another tip for effective maintenance is to follow the manufacturer’s instructions. Regular maintenance of the brine-to-water heat pump can reduce the risk of leaks. If there is an unusually high pressure loss, a leak should be suspected and located quickly to ensure that the system in the house is functioning properly.

As part of maintenance, the brine pipes should also be checked for condensation and the expansion vessel should be checked to ensure that it is functioning properly in order to guarantee efficient insulation and perfect operation of the system.

Professionalize heat pump maintenance with software

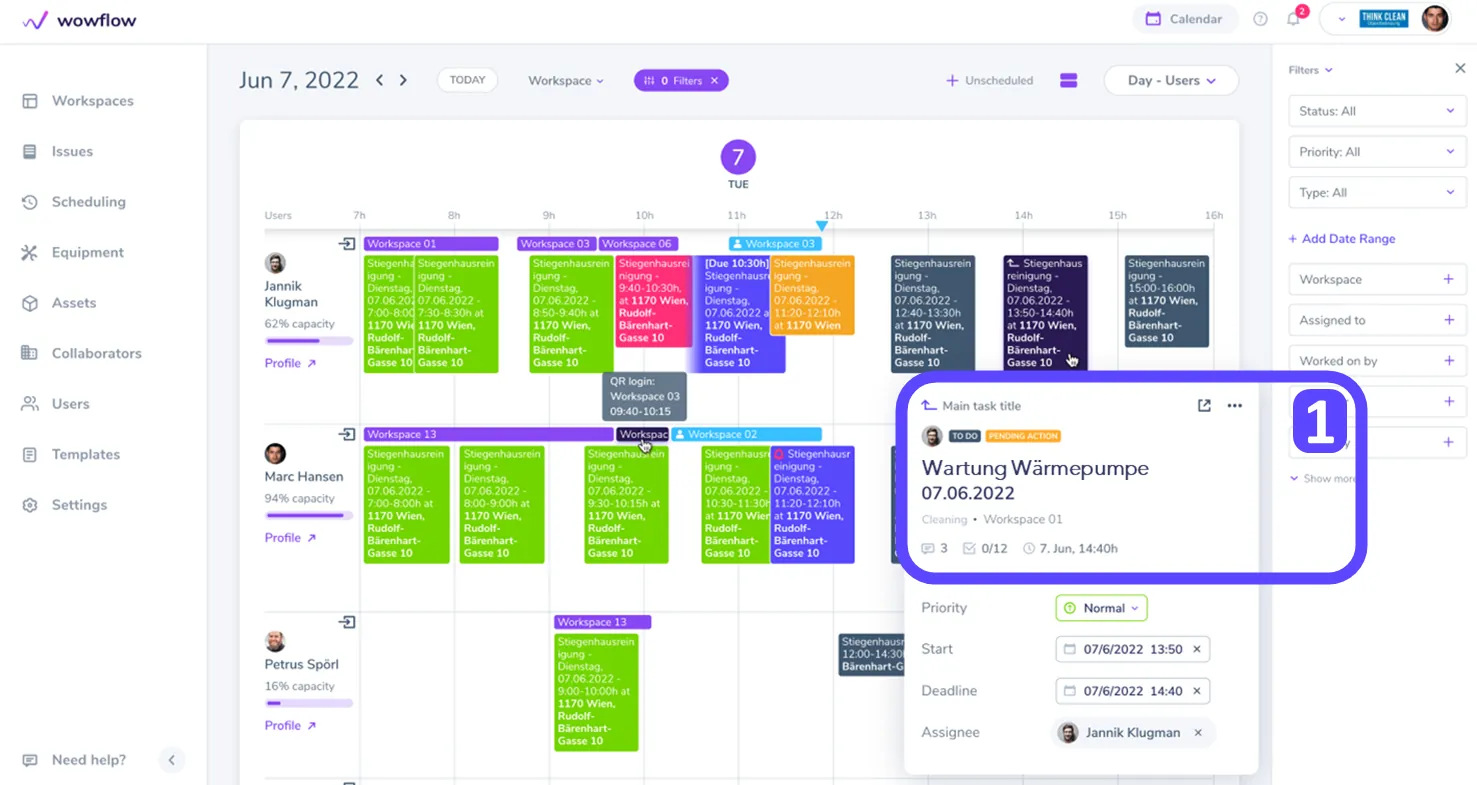

In facility management, Wowflow simplifies and professionalizes the maintenance process considerably.

The facility management software offers these functions:

- With Wowflow, recurring maintenance appointments can be planned and maintenance checklists inserted.

- Wowflow also offers photo documentation to document maintenance work or faults. This is helpful for troubleshooting and future maintenance work.

- With Wowflow, you can create maintenance reports automatically, which considerably simplifies the process of documentation and reporting.

Use Wowflow for your maintenance.

Summary

Regular and effective maintenance of your heat pump is crucial for efficiency, longevity and safety. Although self-maintenance may seem cheaper at first glance, it carries significant risks that can affect the performance of your heat pump as well as your financial and legal security.

By following the manufacturer’s instructions, carrying out regular maintenance and using maintenance management software, you can ensure that your heat pump works optimally and maximizes its service life.

Frequently asked questions

How often do I need to have a heat pump serviced?

Heat pumps should be serviced regularly. A maintenance interval of one to three years is recommended to check filters, pumps and refrigerants. It is recommended to have all heat pumps serviced during this period.

What does heat pump maintenance cost?

The maintenance of most heat pumps costs an average of around 300 euros per year. With air-to-air heat pumps, the costs are somewhat higher due to regular filter changes.

Does a maintenance contract for a heat pump make sense?

Yes, a maintenance contract for a heat pump makes sense in order to ensure the function of components necessary for operation and to guarantee value retention.

How often does a heat pump need to be topped up with refrigerant?

As a rule, refrigerant in heat pumps should never need to be topped up as it is a closed circuit. However, an annual leak test is required if the refrigerant circuit contains more than three kilograms of refrigerant.