Regular maintenance of your ventilation system is essential as it minimizes health risks and saves costs.

In our article, you will learn the essential steps for the professional maintenance of ventilation systems.

Download our free checklist and start improving the operational safety and air quality of your systems immediately.

Why is a ventilation system maintenance checklist important?

In many buildings of the facility management such as event centers, underground car parks and office complexes, ventilation and air conditioning systems are an essential prerequisite for operation.

In the plant maintenance compliance with hygiene standards is particularly important, as neglect leads to the proliferation of bacteria. This can lead to various health problems, including irritation of the mucous membranes, headaches and serious infections.

A maintenance checklist is important to ensure that nothing is forgotten when regularly cleaning and replacing the air filters. It also offers further significant advantages for

building management which we present in the following paragraph.

Top 6 benefits of a ventilation system maintenance checklist

A well-thought-out checklist has a number of advantages:

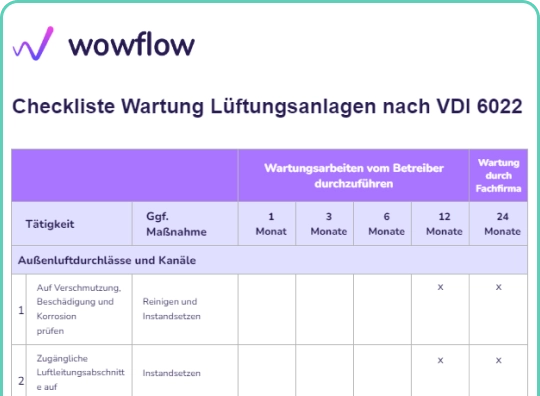

- Documentation and compliance: The use of a maintenance checklist ensures operator responsibility, as it serves as reliable proof of maintenance work carried out. It helps to comply with legal requirements and guidelines such as VDI 6022 for ventilation and air-conditioning systems.

- Cost savings: Regular checks of airflows and heat exchangers can reveal inefficiencies that would otherwise lead to higher operating costs.

- Energy optimization: Maintenance certificates contribute to sustainability in the real estate sector. Energy consumption can be monitored and optimized, leading to cost reductions.

- Air quality: Checking CO₂ sensors and humidity levels helps to maintain good indoor air quality, which is important for the health of users.

- Maintenance planning: The list facilitates time allocation and resource planning for the maintenance team by specifying clear intervals and responsibilities for maintenance tasks. Therefore, it is crucial that you refer to certain protocols and templates for your asset management.

- Extending the service life: The predictive maintenance by means of regular checks using the checklist helps to detect premature wear and tear and rectify it in good time. This extends the service life of the ventilation systems.

In the following, we explain the precise steps that need to be carried out when maintaining ventilation and air conditioning (HVAC) systems.

What is involved in maintaining a ventilation system?

The following activities are required to maintain a ventilation system efficiently and safely:

- Filter change or cleaning: To maintain the air quality and protect the system from contamination.

- Check and clean the ventilation ducts: remove dust and deposits to prevent airflow blockages and contamination.

- Checking and repairing fans: Ensuring efficient operation without unusual noises or vibrations.

- Checking the control and regulation technology: Ensuring the correct functioning of sensors and control systems for optimum control of the ventilation system.

- Inspection and maintenance of exhaust air systems: Checking exhaust air valves and dampers for correct function.

- Function test: Test the entire system for correct functioning and efficiency.

In the following, we will discuss the significance of VDI 6022 and explain what requirements this directive places on the maintenance of air conditioning systems.

What does VDI 6022 say?

VDI 6022 is a guideline that specifies hygiene requirements for ventilation and air conditioning systems. It serves to ensure good indoor air quality by providing specifications for planning, production, execution, operation and servicing of these systems.

Among other things, the directive specifies how and at what intervals ventilation technology components are to be cleaned and maintained, and defines qualifications for maintenance personnel.

How often do ventilation systems need to be checked?

According to VDI Guideline 6022, hygienic inspections of ventilation systems must take place every two years, while air conditioning systems that do not have air humidification equipment should be checked every three years. Systems that include underground components are also subject to a two-year inspection cycle.

Otherwise, routine visual inspections are required to detect potential damage or contamination. Only specialists with appropriate training may carry out this specific hygiene inspection in accordance with VDI 6022.

Digitalization of ventilation system maintenance

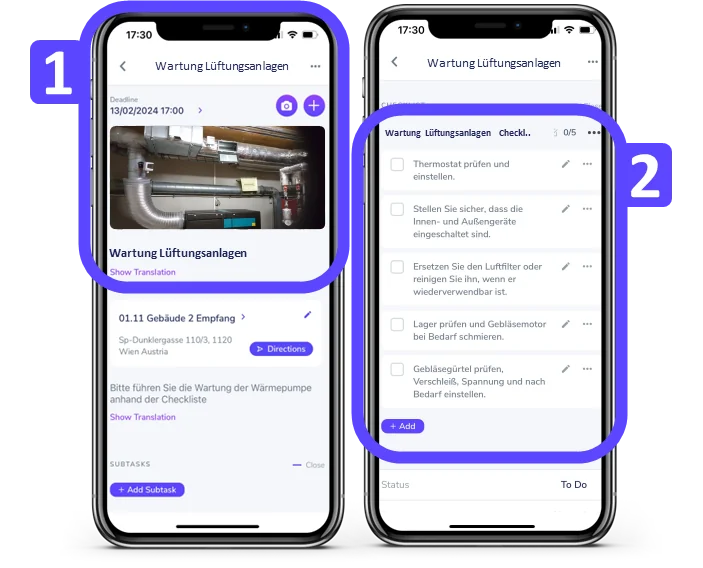

Digital solutions enable efficient implementation and management of maintenance work on ventilation systems. Tools such as Wowflow not only improve transparency and security, but also facilitate communication and documentation.

Wowflow helps you to automate your maintenance planning in three simple steps:

1. Plan your maintenance appointments

Create maintenance plans that you can organize in the calendar view. Make sure you activate notifications so that you don’t miss any inspections.

2. Use digital checklists

Assign tasks quickly and easily and replace paper checklists with digital versions to ensure complete and seamless HVAC system maintenance.

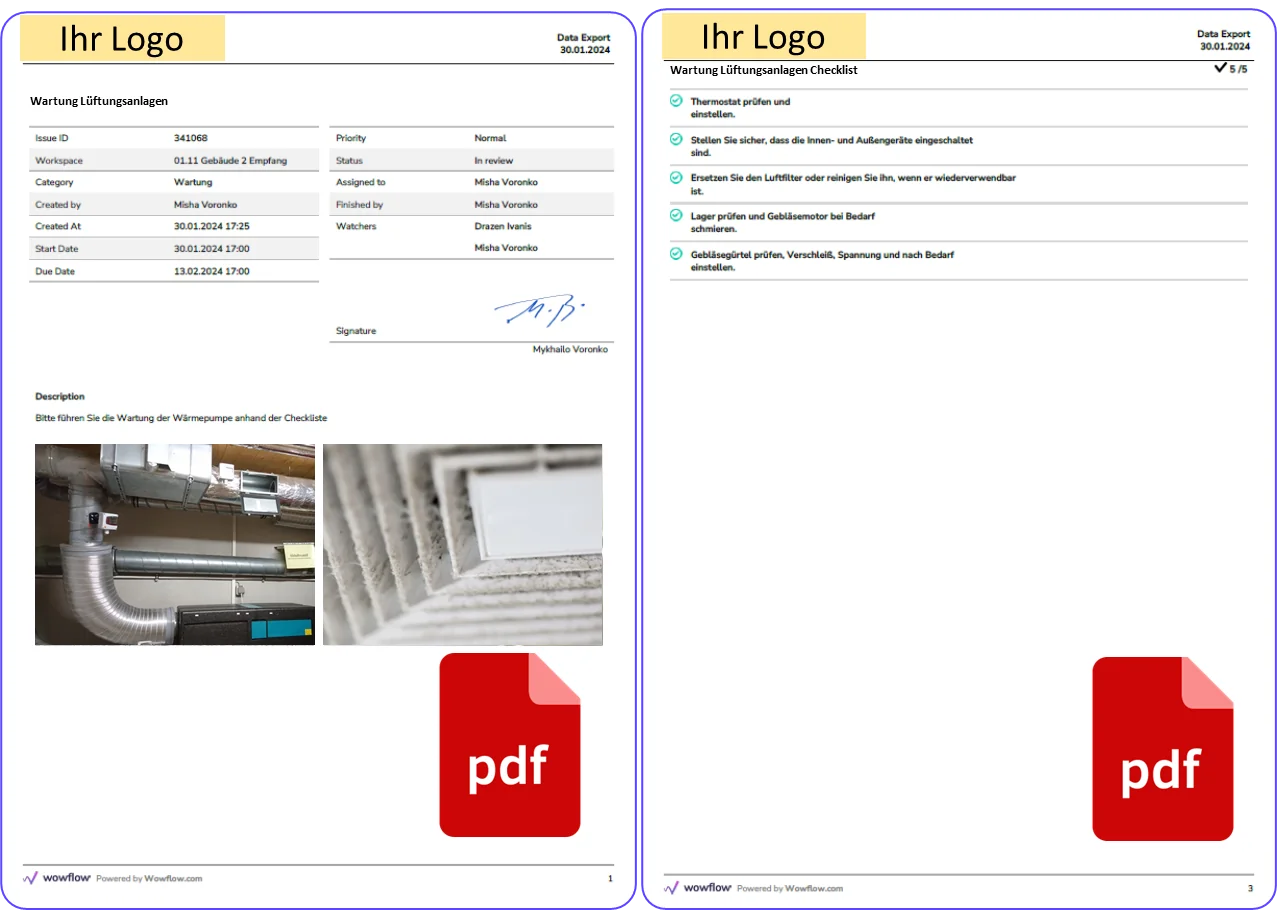

3. Create automated PDF reports

Generate reports with just a few clicks, including images and signatures, and send PDF proofs of work to avoid future confusion or problems.

Discover here the advantages of Wowflow for the maintenance of ventilation systems

Conclusion

The introduction of regular, checklist-based maintenance of ventilation systems is essential in order to extend the service life of the systems and increase their efficiency.

Switching to digital solutions such as Wowflow can revolutionize the maintenance of ventilation systems. It enables a structured. Digital checklists facilitate the tracking of maintenance activities and ensure compliance in building management, while improving efficiency and resource planning.

Start here with Wowflow to optimize the maintenance of your ventilation systems